0102030405

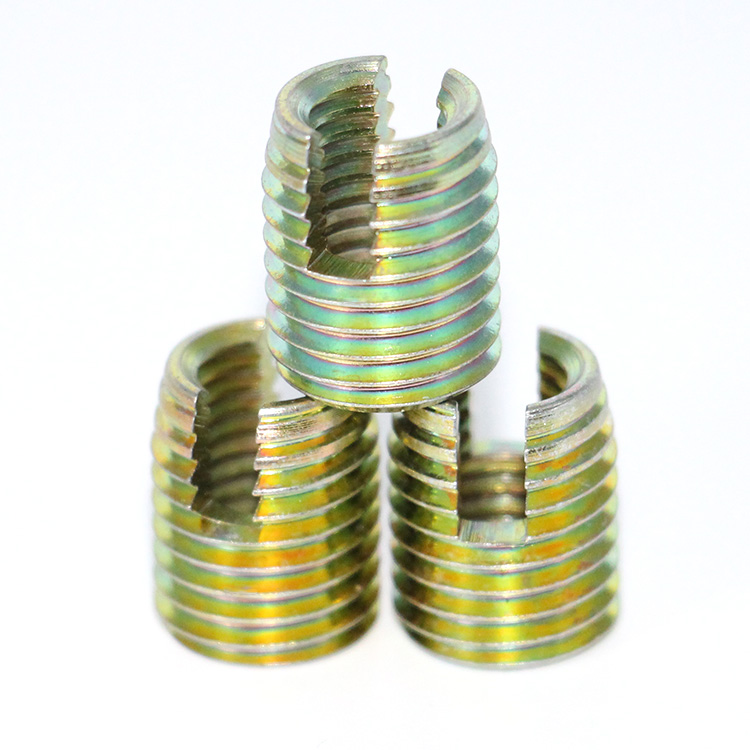

303 Stainless Steel Passivated Three-hole Self-tapping Threaded Insert

Introduction

Self-tapping thread insert a new type of reinforcing the strength of the threaded fasteners, self-tapping thread insert has inner and outer tooth pattern, embedded in plastic, cast iron, aluminum, copper and other soft material, can be formed relatively High-strength internal threaded holes, self-tapping thread insert can also repair damaged internal threads.

Self-tapping thread insert mounted without prior tapping, installation tool can be used directly screwed into specific holes in the base material reserved for the female thread teeth have been crushed and the original can be used the same screw, economic appearance, the new articles but also increases its thread strength.

Self-tapping thread inserts is now widely used in the automotive industry, rail car industry, shipbuilding industry, household appliances, construction machinery, business machines, electronic products, engineering plastics, advanced modular furniture, aluminum die-casting and other industries.

Self-tapping thread insert mounted without prior tapping, installation tool can be used directly screwed into specific holes in the base material reserved for the female thread teeth have been crushed and the original can be used the same screw, economic appearance, the new articles but also increases its thread strength.

Self-tapping thread inserts is now widely used in the automotive industry, rail car industry, shipbuilding industry, household appliances, construction machinery, business machines, electronic products, engineering plastics, advanced modular furniture, aluminum die-casting and other industries.

Material

The materials used in domestic self-tapping thread insert are generally carbon steel and stainless steel.

1. Carbon steel: Color-plated zinc, suitable for surface carburizing heat treatment on aluminum alloy, copper alloy, plastic and other substrates with low engineering strength.

2. Stainless steel SUS303 (304, 316, 316L): suitable for surface passivation treatment on cast iron and other products with higher strength.

1. Carbon steel: Color-plated zinc, suitable for surface carburizing heat treatment on aluminum alloy, copper alloy, plastic and other substrates with low engineering strength.

2. Stainless steel SUS303 (304, 316, 316L): suitable for surface passivation treatment on cast iron and other products with higher strength.

Options | |||||||||

Model |

302 |

303 |

307 |

308 |

|||||

Material |

Stainless steel |

Carbon steel |

|||||||

Standard |

KKV |

||||||||

Model |

Metric |

M3 |

M4 |

M5 |

M6 |

M8 |

M10 |

M12 |

M16 |

|

British |

6-32 |

8-32 |

10-32 |

1/4-20 |

1/2-13 |

5/8-11 |

||

Accuracy |

Green |

Red |

Golden |

Blue |

Non |

Customized |

|||

Use

Self-tapping threaded inserts are self-tapping threaded inserts with slots or holes. Slotted threaded threaded inserts are recommended for most applications. On some materials, this thread insert provides the perfect specific thread lock function. If it still does not work, it is generally recommended to use the 307/308 type, which has made a major breakthrough in the difficulty of material cutting. This product not only has a very thick wall, but also has three circular holes with cutting ability scattered on the wall. The 307/308 product is especially suitable for the case where the material thickness is not too wide.

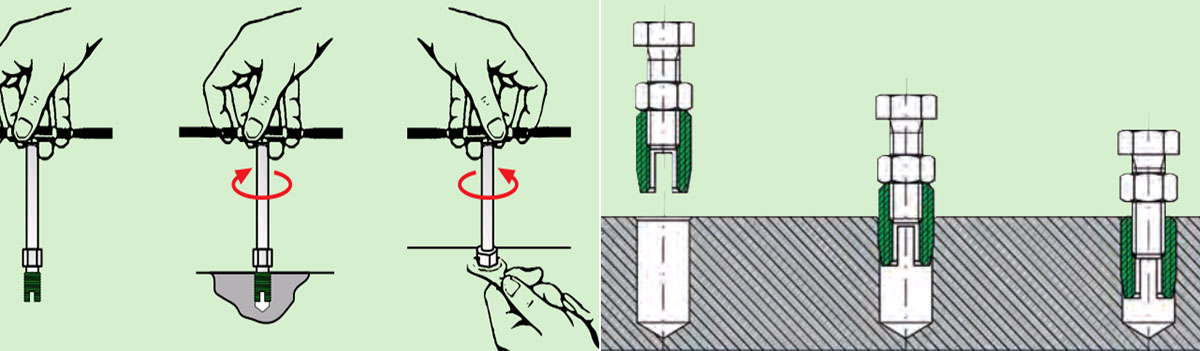

Manual installation:

Use the special thread insert installation tool. Refer to the figure below for the specific operation method. The end of the tool in the figure is a quadrangle head, which can be connected with a manual tapping wrench

Manual installation:

Use the special thread insert installation tool. Refer to the figure below for the specific operation method. The end of the tool in the figure is a quadrangle head, which can be connected with a manual tapping wrench

Electric installation:

The DiI type of HRT numerical control suspension thread insert electric installation machine designed by AVIC can complete the installation of thread insert with high efficiency and high quality.

The DiI type of HRT numerical control suspension thread insert electric installation machine designed by AVIC can complete the installation of thread insert with high efficiency and high quality.

Installation precautions:

●It is necessary to select the appropriate drilling size according to different matrix materials;

●If the hole is large, it is easy to take out the thread insert when the mounting rod exits;

●If the hole is small, the installation of the thread insert will be difficult or even hindered.

●At the beginning of installation, it is necessary to ensure the perpendicularity between the thread insert and the base surface of the installation hole, otherwise it is easy to deviate and cause unsuccessful installation.

●It is necessary to select the appropriate drilling size according to different matrix materials;

●If the hole is large, it is easy to take out the thread insert when the mounting rod exits;

●If the hole is small, the installation of the thread insert will be difficult or even hindered.

●At the beginning of installation, it is necessary to ensure the perpendicularity between the thread insert and the base surface of the installation hole, otherwise it is easy to deviate and cause unsuccessful installation.

Purpose

It is widely used in aerospace components, locomotive, high-voltage electrical appliances, automotive power, wind power, nuclear power, communication and electrical industries. It is used in aluminum, magnesium, copper alloy, plastic, plexiglass, plywood, steel, cast steel and cast iron to make it more tough and firm.

FAQ

Q: What’s your business scope?

A: OEM Service.

Q.How to contact us ?

A: You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp as you like.

Q. What information should I give to you for inquiry?

A: If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect.

Q. What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment. Except for custom products.

Q. What about the payment terms?

A: Generally EXW and we can also consult accroding to your requirement.

A: OEM Service.

Q.How to contact us ?

A: You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp as you like.

Q. What information should I give to you for inquiry?

A: If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect.

Q. What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment. Except for custom products.

Q. What about the payment terms?

A: Generally EXW and we can also consult accroding to your requirement.