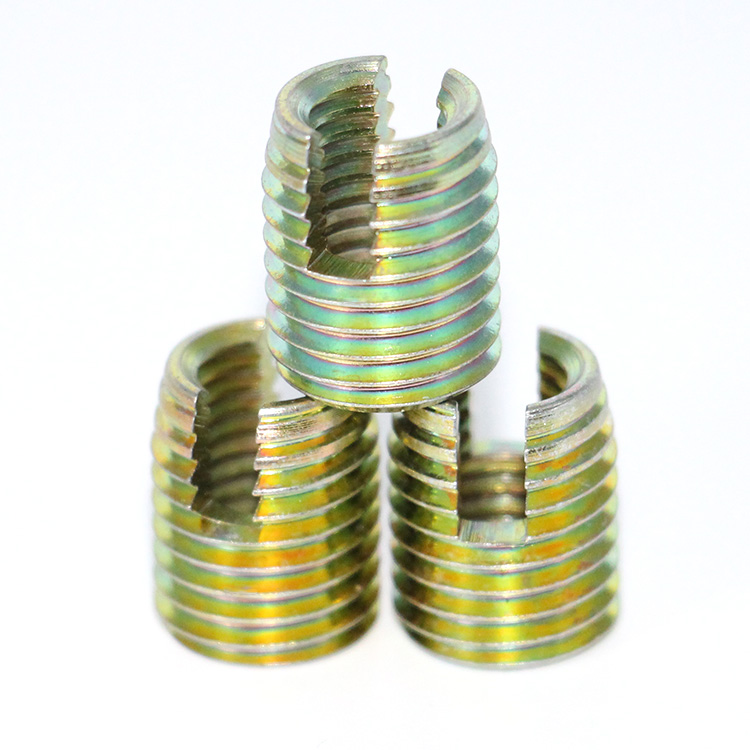

Dry film lubrication wire threaded inserts for metal

Dry film lubrication wire threaded inserts for metal

Dry film lubricant coated wire thread inserts are used in mildly corrosive or high-temperature environments. Dry film lubricants consist of small particles suspended from a solid lubricant in an organic or inorganic binder, such as molybdenum disulfide or polytetrafluoroethylene.

They are applied to a metal surface without grease in the form of a film (5μm~ 20μm). By carefully selecting the right additives and solvents, special lubricants suitable for most industrial applications at around 315°C can be made. The ultra high temperature lubricant coating can be used in high temperature conditions of 425°C. bokcoil thread braces can be applied with a dry film lubricant in unfinished conditions or after chromium coating treatment for greater corrosion protection.

Wire Thread Insert Parameters

| Product name | Wire thread insert |

| Material | SUS304/SUS316/SUS321/InX750/Brass/Customized |

| Surface color | None / Eco-friendly plating |

| Surface coating | Silver/tin/cadmium/zinc/other |

| Thread type | Metric,Inc UNC, UNF |

| Metric Size | M1.4*0.3P~M85*6.0P |

| Inch UNC Size | 1-64~11/2“-6 |

| Inch UNF Size | 4-48~11/2“-12 |

| Production standard | MS21209/DIN8140/N926/ITN32760/MO-44421 |

Wire thread insert Common specifications parameter list

|

Diameter |

Pitch |

d |

(Dz) |

Bit diameter |

|

|

(d) |

(P) |

(do) |

|||

| Metric | |||||

|

M1.6 |

0.35 |

1d/1.5/2d/2.5d/3d |

2.08-2.18 |

1.7 |

|

|

M2 |

0.4 |

1d/1.5/2d/2.5d/3d |

2.60~2.80 |

2.1 |

|

|

M2.5 |

0.45 |

1d/1.5/2d/2.5d/3d |

3.30~3.50 |

2.6 |

|

|

M3 |

0.5 |

1d/1.5/2d/2.5d/3d |

3.80~4.00 |

3.2 |

|

|

M4 |

0.7 |

1d/1.5/2d/2.5d/3d |

5.05~5.25 |

4.2 |

|

|

M5 |

0.8 |

1d/1.5/2d/2.5d/3d |

6.35~6.60 |

5.2 |

|

|

M6 |

1 |

1d/1.5/2d/2.5d/3d |

7.60~7.85 |

6.3 |

|

|

M7 |

1 |

1d/1.5/2d/2.5d/3d |

8.65~8.90 |

7.3 |

|

|

M8 |

1.25 |

1d/1.5/2d/2.5d/3d |

9.85~10.10 |

8.4 |

|

|

M10 |

1.25 |

1d/1.5/2d/2.5d/3d |

12.10~12.50 |

10.4 |

|

|

M11 |

1.5 |

1d/1.5/2d/2.5d/3d |

13.10~13.50 |

11.5 |

|

|

M12 |

1.75 |

1d/1.5/2d/2.5d/3d |

14.40~14.80 |

12.5 |

|

|

Inch |

|||||

|

2-56 (0.086) |

0.435 |

1d/1.5d/2d/2.5d |

2.7~2.9 |

2.4 |

|

|

4-40 (0.112) |

0.635 |

1d/1.5d/2d/2.5d |

3.6~4.0 |

3.1 |

|

|

5-40 (0.125) |

0.635 |

1d/1.5d/2d/2.5d |

4.0~4.4 |

3.4 |

|

|

6-32 (0.138) |

0.794 |

1d/1.5d/2d/2.5d |

4.5~4.9 |

3.8 |

|

|

8-32 (0.164) |

0.794 |

1d/1.5d/2d/2.5d |

5.2~5.6 |

4.4 |

|

|

10-24 (0.190) |

1.058 |

1d/1.5d/2d/2.5d |

6.2~6.6 |

5.2 |

|

|

12-24 (0.216) |

1.058 |

1d/1.5d/2d/2.5d |

6.8~7.2 |

5.8 |

|

|

1/4"-20 |

1.27 |

1d/1.5d/2d/2.5d |

8.0~8.4 |

6.7 |

|

|

5/16"-18 |

1.411 |

1d/1.5d/2d/2.5d |

9.7~10.2 |

8.4 |

|

|

3/8"-16 |

1.588 |

1d/1.5d/2d/2.5d |

11.5~12.0 |

10 |

|

Other surface treatments for wire threaded inserts

For steel wire threaded inserts made of 304 stainless steel, the surface treatments available are:

1. No treatment, natural surface

2. Environmentally friendly colour plating, according to customer needs can be plated in purple, green, blue, red. In industries where large quantities of threaded inserts are required, colour plated wire threaded inserts help to identify whether they are installed or not. The different colors of the wire threaded inserts are also very convenient for visual management.

3. Cadmium plating, cadmium (cd) plated steel wire threaded inserts corrosion resistance, lubrication, wear resistance, electrical conductivity, electromagnetic properties, heat resistance is stronger.

4. Silver-plated, silver-plated steel threaded bushings can be installed in a variety of shell materials, including magnesium alloys, aluminium alloys and corrosion and heat-resistant materials, mainly used to reduce the screw threads in the high-temperature state of the bonding effect.

5. Tin-plated, tin-plated steel wire threads inserts have the biggest advantage of better corrosion resistance, for corrosion resistance has high requirements, you can consider tin-plated coating of steel wire threads.

6. Dry film lubrication for mild corrosion or high temperature environment.