0102030405

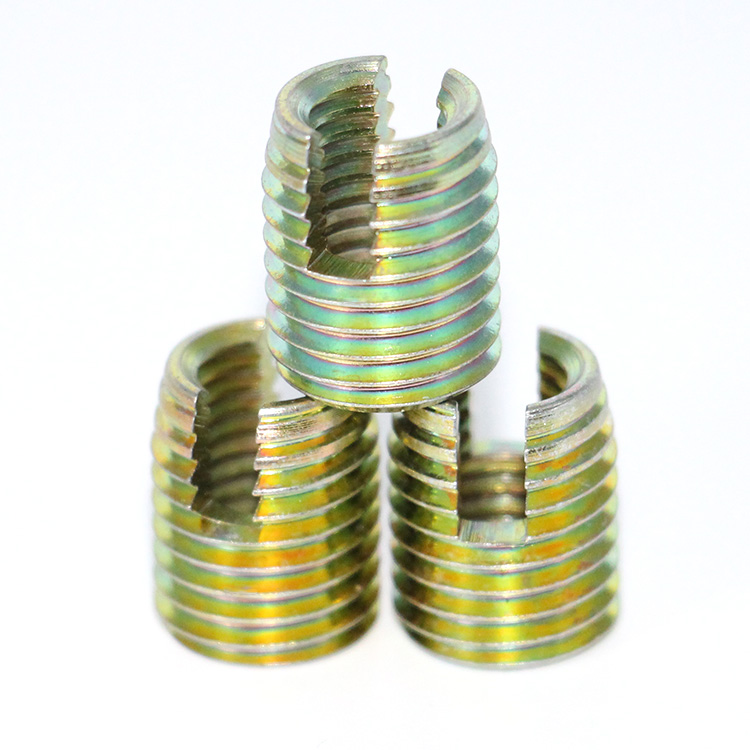

High Speed Steel thread tap for Wire Thread Inserts

High Speed Steel thread tap for Wire Thread Inserts

Thread tap is an essential tool in the installation of wire threaded inserts

To tap the AVIC-Flight Plus tapped hole, system dependent original AVIC-Flight taps must be used. We have suitable manual and machine taps on offer. The overview provides all necessary information. The standard taps from the AVIC-Flight system comply with almost all practical requirements. For critical chip removal requirements, such as materials difficult to machine (stainless and heat-resisting steels, different steel and titanium alloys), we offer special machine taps. The overview provides the machine taps for the respective materials including recommended guide values for cutting speed.

■Straight groove

Cutting angle of 10 °, rotary cutting head, for through hole, At the initial stage of tapping, it is necessary to screw in 4 times the pitch, and a deep hole shall be drilled in advance for the blind hole.

For materials with strength less than or exceeding 700 n / mm2.

For tapping through holes.

■Spiral groove

Machine tap, 45 ˚ Spiral groove, right rotation, cutting angle 15 ˚,

For blind holes, it is necessary to screw in twice the pitch at the initial stage of tapping.

For materials with strength less than 700 n / mm2.

It can be used to tap blind holes.

■Extrusion tap

Suitable for processing non-ferrous metals with high toughness, especially copper and aluminum alloy castings;

Realize chip free machining, strengthen the strength of the tapping teeth, and there is no transition thread;

The internal thread hole processed by extrusion process has high tensile and shear strength and good surface roughness.

Product Tutorials

1. Drilling - Use a tap of the appropriate size to drill the hole where the threaded insert is to be installed.

2. Tapping - Use the corresponding type of special tap to align with the drilled threaded hole and rotate it in to form a thread.

3. Installation-Rotate the wire thread insert to the head of the installation tool.

4. Screw-in: Then align the threaded hole with the threaded hole already formed, and use the installation tool to install the wire thread insert into the threaded hole. Withdraw the tool after installing the wire threaded insert in place.

5. Tail shank: take out the tail shank removal tool, align the wire threaded insert installation tail shank, with the appropriate force to knock, the tail shank can be successfully removed!

6.Successful installation-The wire thread insert is installed successfully

Related tools

Regarding thread repair tools, we have some other related tools as follows ,These are the tools that are used when working with wire threaded inserts and are widely used in areas where thread repair is required.