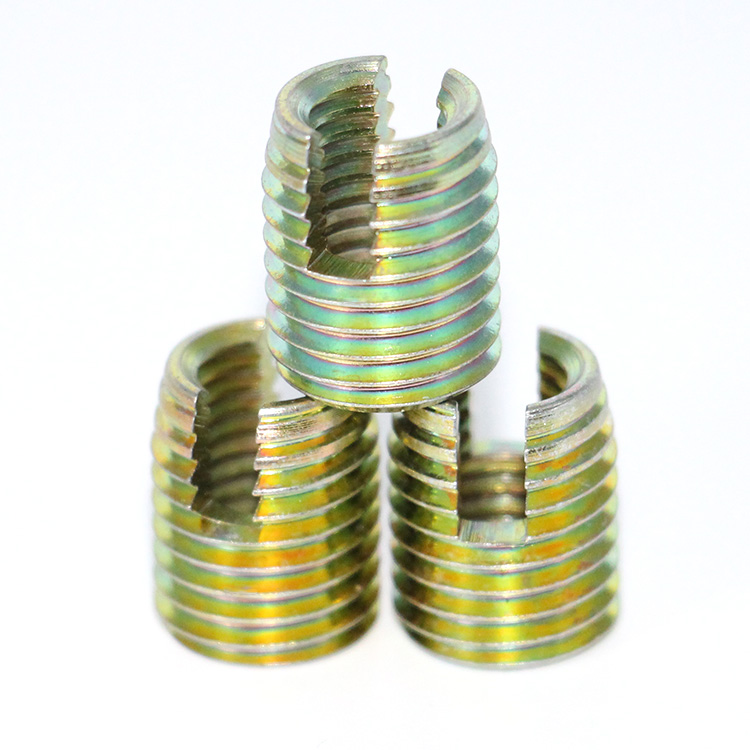

Metric Blind hole cone wire thread insert For blind holes

Blind hole cone wire thread insert For blind holes

Blind hole wire thread insert, as the name suggests, is only used for blind holes (also known as blocked holes) internal thread enhancement and repair. It has no mounting handle, is the use of wire thread insert front end of 2 to 3 turns of the cone and special tools to screw it into the threaded hole.

There is no need to remove the mounting handle, eliminating the need for traditional steel wire thread insert to remove the mounting handle and the impact of the mounting handle residue.

When screwing in, the cone part of the blind hole wire thread insert can enter the conical internal thread of the front end incomplete tooth generated by the tap guide cone, and it is not necessary to increase the length of the internal thread of the blind hole wire thread insert.

It is also divided into ordinary type and locking type like the traditional wire thread insert.

Blind hole wire thread insert parameters Parameters

Product name |

Blind hole wire thread insertt |

Material |

SUS304/SUS316/SUS321/InX750/Brass/Customized |

Surface color |

None / Eco-friendly plating |

Surface coating |

Silver/tin/cadmium/zinc/other |

Thread type |

Metric |

Common type |

M3-M39 |

Lock type |

M3-M12 |

Common blind hole wire thread insert parameters | |||||

(mm) |

P |

d1 min |

d1 max |

d2 min |

d2 max |

M3 |

0.5 |

3.8 |

4.35 |

3.11 |

3.22 |

M4 |

0.7 |

5.05 |

5.6 |

4.15 |

4.29 |

M5 |

0.8 |

6.25 |

6.8 |

5.17 |

5.33 |

M6 |

1 |

7.58 |

7.95 |

6.22 |

6.41 |

M7 |

1 |

8.58 |

9.2 |

7.22 |

741 |

M8 |

1.25 |

9.85 |

10.35 |

8.27 |

8.48 |

M10 |

1.5 |

12.1 |

12.8 |

10.32 |

10.56 |

M12 |

1.75 |

14.5 |

15 |

12.38 |

12.65 |

M14 |

2 |

16.87 |

17.87 |

14.43 |

14.73 |

M16 |

2 |

18.87 |

19.9 |

16.43 |

16.73 |

M18 |

2.5 |

21.4 |

22 |

18.54 |

18.9 |

M20 |

2.5 |

23.46 |

24.4 |

20.54 |

20.9 |

M22 |

2.5 |

25.61 |

26.9 |

22.54 |

22.9 |

M24 |

3 |

28.15 |

29.1 |

24.65 |

25.05 |

M27 |

3 |

31.15 |

32.4 |

27.65 |

28.05 |

M30 |

3.5 |

34.7 |

35.81 |

30.76 |

31.21 |

M33 |

3.5 |

37.7 |

39.01 |

33.76 |

34.21 |

M36 |

4 |

41.33 |

42.67 |

36.87 |

37.35 |

M39 |

4 |

44.33 |

45.75 |

39.87 |

40.35 |

Lock type blind hole wire thread insert parameters | |||||

(mm) |

P |

d1 min |

d1 max |

d2 min |

d2 max |

M3 |

0.5 |

3.8 |

4.35 |

3.11 |

3.22 |

M4 |

0.7 |

5.05 |

5.6 |

4.15 |

4.29 |

M5 |

0.8 |

6.25 |

6.8 |

5.17 |

5.33 |

M6 |

1 |

7.58 |

7.95 |

6.22 |

6.41 |

M7 |

1 |

8.58 |

9.2 |

7.22 |

7.41 |

M8 |

1.25 |

9.85 |

10.35 |

8.27 |

8.48 |

M10 |

1.5 |

12.1 |

12.8 |

10.32 |

10.56 |

M12 |

1.75 |

14.5 |

15 |

12.38 |

12.65 |

Surface treatment

For steel wire threaded inserts made of 304 stainless steel, the surface treatments available are:(The same applies to Blind hole wire thread insert)

1. No treatment, natural surface

2. Environmentally friendly colour plating, according to customer needs can be plated in purple, green, blue, red. In industries where large quantities of threaded inserts are required, colour plated wire threaded inserts help to identify whether they are installed or not. The different colors of the wire threaded inserts are also very convenient for visual management.

3. Cadmium plating, cadmium (cd) plated steel wire threaded inserts corrosion resistance, lubrication, wear resistance, electrical conductivity, electromagnetic properties, heat resistance is stronger.

4. Silver-plated, silver-plated steel threaded bushings can be installed in a variety of shell materials, including magnesium alloys, aluminium alloys and corrosion and heat-resistant materials, mainly used to reduce the screw threads in the high-temperature state of the bonding effect.

5. Tin-plated, tin-plated steel wire threads inserts have the biggest advantage of better corrosion resistance, for corrosion resistance has high requirements, you can consider tin-plated coating of steel wire threads.

6. Dry film lubrication for mild corrosion or high temperature environment.