0102030405

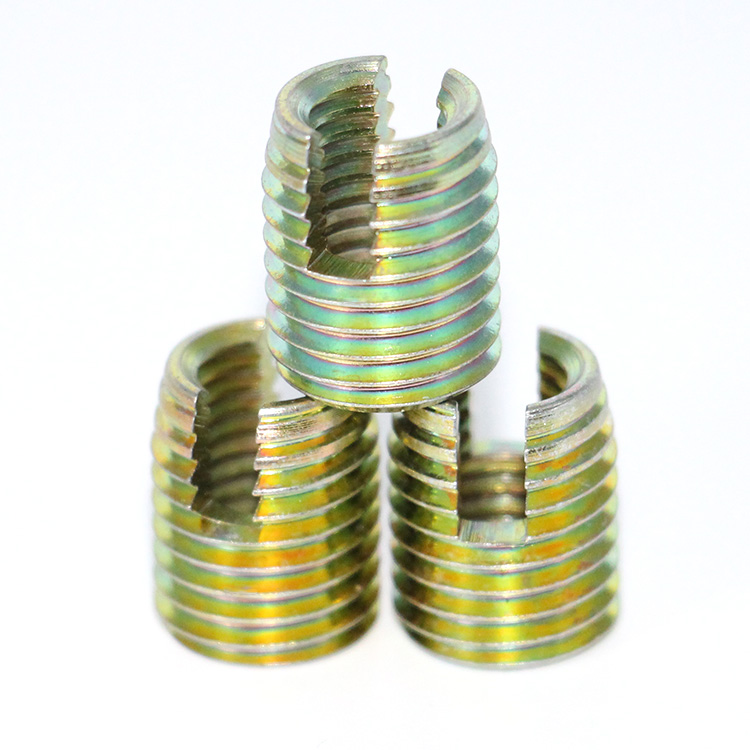

Wire thread insert Manual installation tool for thread insert install

Wire thread insert Manual installation tool for thread insert install

Hand mounting tool with pre installed guide .

It is used to install AVIC-Flight wire Thread Inserts for special applications and fine thread.

It is not the only manual installation tool of AVIC-Flight Thread Inserts

The head of the manual installation tool has two different structures, one is the threaded head and the other is the slotted head. You can choose different structures according to different installation environments.

Product attribute

| Product name | Wire thread insert Manual Installation Tools |

| Customized support | Yes |

| Brand Name | Avic-Flight |

| Size | Inch size/Metric size/Customized size |

| Material | Bearing Steel/HSS/HSSE/Carbide |

| Usage | Thread insert insall |

| Place of Origin | China henan |

Wire thread insert Installation process

■Fitting the thread insert

Installation is possible either from hand or by the use of a mechanical installation tool or an automatic installation machine. The AVIC-Flight thread insert is screwed onto the installation mandrel with its tang pointing downwards (3A), fitted into the pre-stressing cartridge (3B) or placed onto the fly-over tool (3C) and the equipment is then placed over the tapped hole.

■Installation

By means of revolving the thread tang (4A), the mandrel (4B) or the fly-over tool (4C) by hand or starting the driver the thread insert is screwed in. It must be installed with a minimum of 0.25 P

underneath the surface.

■Breaking the tang off

For creation of a through-hole thread the tang is broken off at the notch. This is completed by the use of a tang break-off tool (5A and 5B). For threads of M14 fine and normal gradients, a pair of pointed

pliers’ (5C) can break off the tang.

The tang must not be removed for blind hole threads if the maximum screw-in depth L6 of the screw is adhered to.

Related tools

Regarding thread repair tools, we have some other related tools as follows ,These are the tools that are used when working with wire threaded inserts and are widely used in areas where thread repair is required.

1.Thread tap: used for the processing of the internal thread of the wire thread insert. Since the external thread of the wire thread insert is a non-standard thread, this type of tap is different in size from the ordinary M tap.

2.Installation wrench: used to install the wire thread insert in the threaded hole. The basic principle is to make the wire thread thread insert pass through a section of the guide thread to force the outer diameter of the wire thread insert to shrink so that it can be inserted into the thread hole smoothly. It is divided into manual type And automatic type.

3.Mounting spindle:Mounting spindles are threaded spindles for use with pneumatic or electric tools and can also be used for manual mounting.

4. Breaker(Thruster): The purpose of the breaker is mainly to break the installation handle of the wire threaded sleeve, especially for the through hole, the installation handle must be broken.

5.Disassembly tool: used to take out the threaded thread insert installed in the threaded hole of the base. For the thread insert that needs to be replaced after long-term use, and when it needs to be taken out due to improper installation or thread tripping during installation, etc. use.

6.Thread plug gauge: used to detect the internal thread bottom hole of the wire thread insert. After the wire thread insert is installed, the accuracy of the internal thread formed depends on the profile manufacturing tolerance of the wire thread insert and the internal thread bottom hole of the wire thread insert tolerance.

7.Electric Installation Tools-Electric installation tools used in conjunction with mounting spindles can greatly improve mounting efficiency and are suitable for high volume installations.

8.Thread repair tool set: Tool set Contains drills, taps, mounting wrenches and breaker as well as some wire threaded inserts. This set of tools allows for the complete installation of wire threaded inserts. Our tool sets are customizable, allowing customers to customize the set with the tools they need and the type they want.

9.Motorized mounting table:The motorized mounting table consists of an adjustable table, a motorized mounting tool, and can be used with different sizes of threaded spindles to achieve quick installation of wire threaded inserts. It is suitable for small workpieces that need to be installed in large quantities.