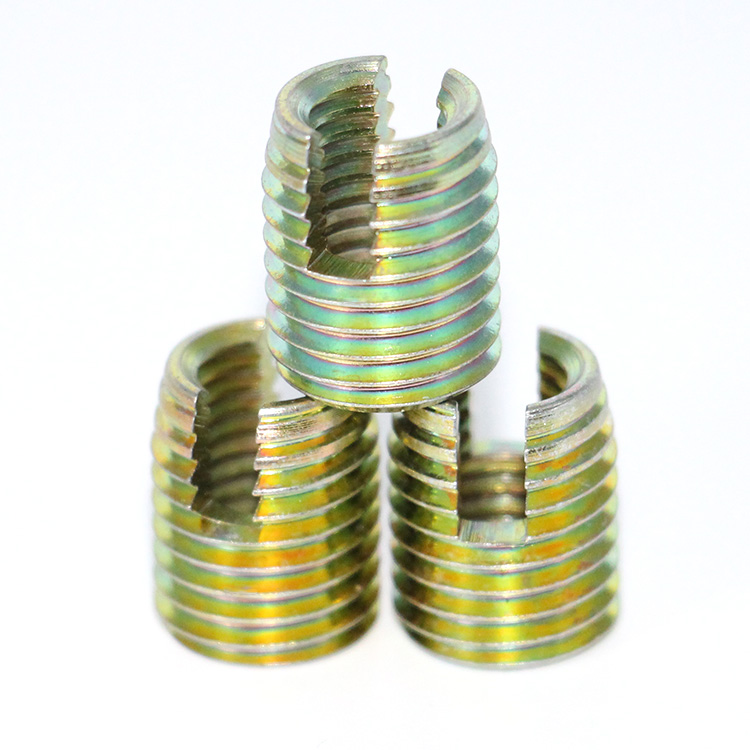

302 series Metric Inch Self tapping thread insert For Metals and Plastics

302 series Metric Inch Self tapping thread insert For Metals and Plastics Feature

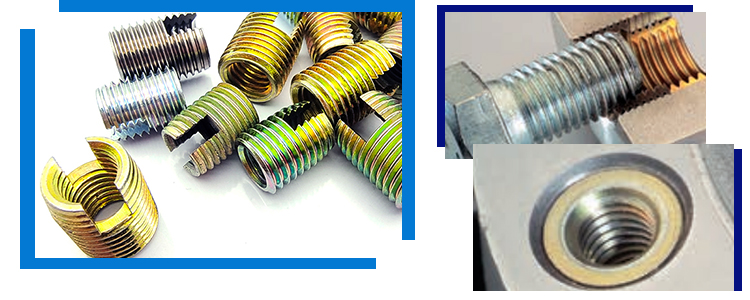

◆Provides strong female threads on soft substrates to accommodate multiple repairs and disassembly needs;

◆Can effectively repair damaged internal threads;

◆Self-tapping sleeves are used after die casting, injection molding, or other manufacturing processes, so they allow for simplified product mix and improved yields;

◆Self-tapping bushings can withstand high loads, so smaller inserts can be used, resulting in a more compact product design.

302 series Self tapping thread insert parameter

Product name |

302/303 series Self tapping thread insert |

Material |

Steel Zn/SUS303/Customized |

Surface color |

Galvanized/Natural color |

Galvanizing: yellow/blue/Colored | |

Thread type |

Metric,Inc UNC, UNF |

Model Number |

M2-M24/Customized |

Function |

Assembly, threaded connection/fastening/conversion |

Reliability test |

Mechanical dimentions, hardness test. salt spray endurance test |

Table of dimensions for self-tapping threaded inserts

Metric size Type 302 Self-Tapping Thread Insert | |||||

|

Internal thread |

External thread

|

Length |

Guideline values for receiving hole diameter |

Minimum borehole depth for blind holes |

|

A |

E |

P |

B |

L |

T |

M2 |

4.5 |

0.5 |

6 |

4.2 to 4.3 |

8 |

M2.5 |

4.5 |

0.5 |

6 |

4.2 to 4.3 |

8 |

M3 |

5 |

0.5 |

6 |

4.7 to 4.8 |

8 |

M3.5 |

6 |

0.75 |

8 |

5.6 to 5.7 |

10 |

M4 |

6.5 |

0.75 |

8 |

6.1 to 6.2 |

10 |

M5 |

8 |

1 |

10 |

7.5 to 7.6 |

13 |

M6(a) |

9 |

1 |

12 |

8.5 to 8.6 |

15 |

M6 |

10 |

1.5 |

14 |

9.2 to 9.4 |

17 |

M8 |

12 |

1.5 |

15 |

11.2 to11.4 |

18 |

M10 |

14 |

1.5 |

18 |

13.2 to13.4 |

22 |

M12 |

16 |

1.5 |

22 |

15.2 to15.4 |

26 |

M14 |

18 |

1.5 |

24 |

17.2 to17.4 |

28 |

M16 |

20 |

1.5 |

22 |

19.2 to19.4 |

26 |

M18 |

22 |

1.5 |

24 |

21.2 to21.4 |

29 |

M20 |

26 |

1.5 |

27 |

25.2 to25.4 |

32 |

M22 |

26 |

1.5 |

30 |

25.2 to25.4 |

36 |

M24 |

30 |

1.5 |

30 |

29.2 to29.4 |

36 |

M27 |

34 |

1.5 |

30 |

33.2 to33.4 |

36 |

M30 |

36 |

1.5 |

40 |

35.2 to35.4 |

46 |

Inch size Type 302 Self-Tapping Thread Insert | |||||

Internal thread |

External thread

|

Length |

Minimum borehole depth |

||

UNC |

UNF |

E |

P |

B |

T |

4-40 |

4-48 |

5 |

0.5 |

6 |

8 |

6-32 |

6-40 |

6 |

0.75 |

8 |

10 |

8-32 |

8-36 |

6.5 |

0.75 |

8 |

10 |

10-24 |

10-32 |

8 |

1 |

10 |

13 |

1/4-20 |

1/4-28 |

10 |

1.5 |

14 |

17 |

5/16-18 |

5/16-24 |

12 |

1.5 |

15 |

18 |

3/8-16 |

3/8-24 |

14 |

1.5 |

18 |

22 |

7/16-14 |

7/16-20 |

16 |

1.5 |

22 |

26 |

1/2-13 |

1/2-20 |

18 |

1.5 |

22 |

28 |

5/8-11 |

5/8-18 |

20 |

1.5 |

22 |

27 |

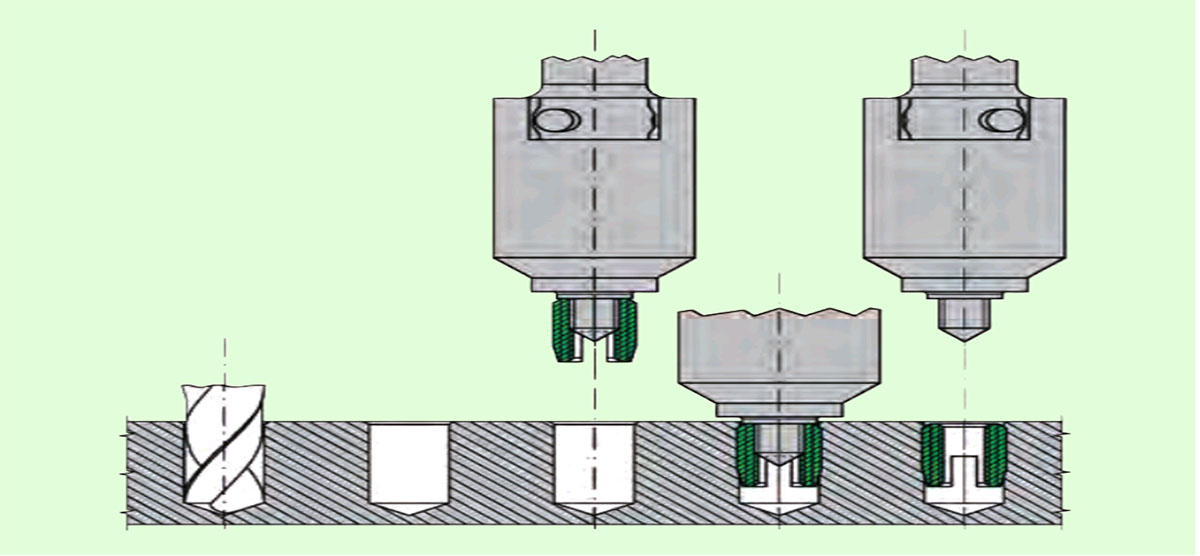

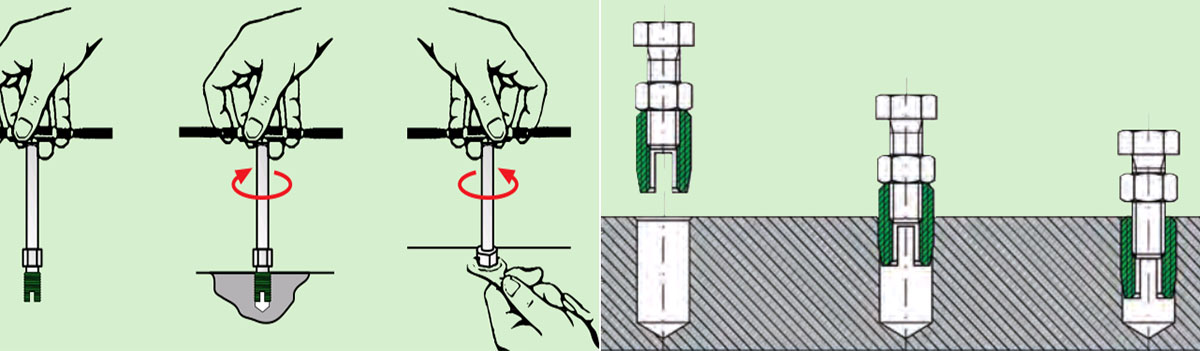

Product Installation Steps

Manual Installation:

Use the special thread insert installation tool. Refer to the figure below for the specific operation method. The end of the tool in the figure is a quadrangle head which can be connected with a manual tapping wrench.

Electric Installation

1. Position the workpiece exactly,so that drilling and machines -spindle axially parallel to each other lie (do not tilt).Machine to the exact screwing depth adjust (approx. 0.1 to 0.2 mm under the workpiece surface ).

2. Machine operating lever actuate. When you start screwing in, the rota table outer sleeve of the tool must be in line with what is visible on the outside stop pins so that they of these clockwise with -is taken.

3. Add Self tapping thread insert to the tool (Slot or cutting hole according to bottom) and 2 to 4 turns hold on for a long time.

4. Machine operating lever continue to operate and take the tool with you Guide Self tapping thread insert to the hole until the Self tapping thread insert gets into the borehole cuts in. The further turning takes place without feed actuation.

5. Switch on reverse (depending on type and the device is constructed this automatically using a limit switch or depth finder). Hard landing of the tool onto the workpiece avoid at all costs; otherwise exists

Risk of breakage for tools and Self tapping thread insert. In addition, The play-free tight fit of the Self tapping thread insert is destroyed and the pull-out strength is reduced. The screwing speed may need to be adjusted to the required speed Switchover time can be adjusted.