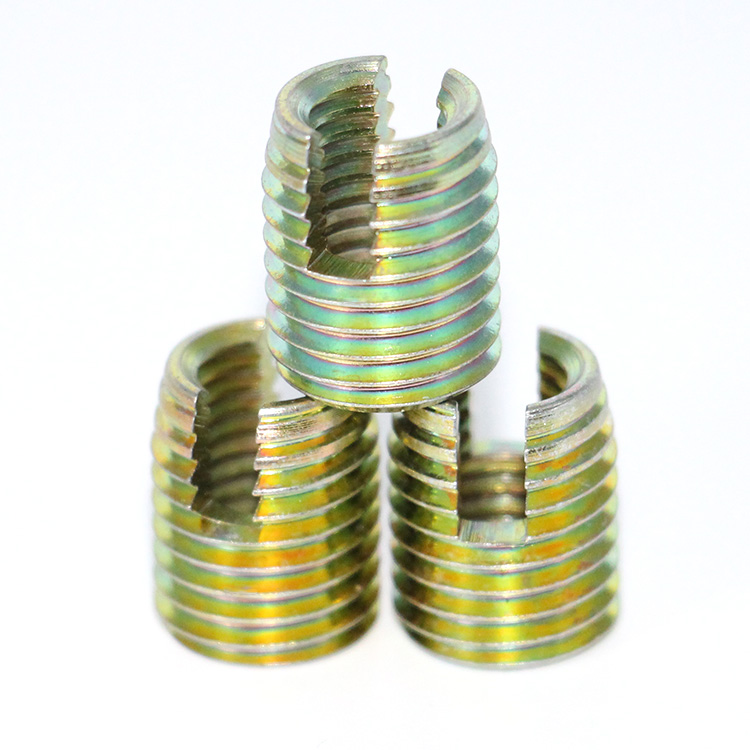

304 Stainless Steel Thread Repair wire thread insert

304 Stainless Steel Thread Repair wire thread insert

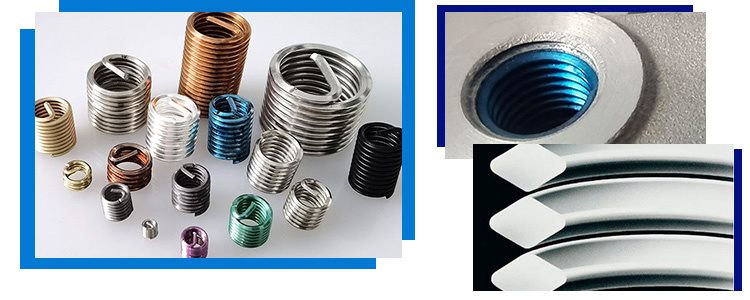

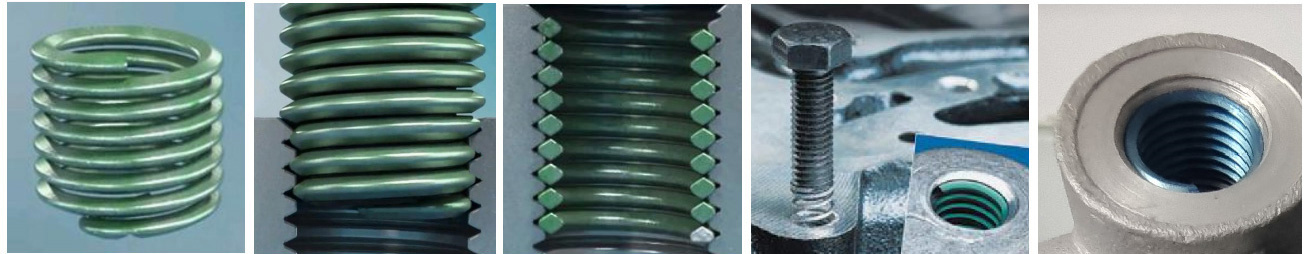

Our wire thread inserts cover a wide range of thread sizes in metric and inch threads in regular and locking unc and unf threads. They are often made of 304 stainless steel, but can also be supplied in Inx750, 321 stainless steel, etc. on request.

Wire thread inserts can also be cadmium-plated, silver-plated, zinc-plated, tin-plated, colored, dry-film lubricated and other special treatments.

304 Stainless Steel Thread Repair Wire Thread Insert

Product name |

Wire thread insert |

Material |

SUS304/SUS316/SUS321/InX750/Brass/Customized |

Surface color |

None / Eco-friendly plating |

Surface coating |

Silver/tin/cadmium/zinc/other |

Thread type |

Metric,Inc UNC, UNF |

Metric Size |

M1.4*0.3P~M85*6.0P |

Inch UNC Size |

1-64~11/2“-6 |

Inch UNF Size |

4-48~11/2“-12 |

Production standard |

MS21209/DIN8140/N926/ITN32760/MO-44421 |

Wire thread insert Common specifications parameter list

Diameter |

Pitch |

d |

(Dz) |

Bit diameter |

|

(d) |

(P) |

(do) |

|||

Metric | |||||

M1.6 |

0.35 |

1d/1.5/2d/2.5d/3d |

2.08-2.18 |

1.7 |

|

M2 |

0.4 |

1d/1.5/2d/2.5d/3d |

2.60~2.80 |

2.1 |

|

M2.5 |

0.45 |

1d/1.5/2d/2.5d/3d |

3.30~3.50 |

2.6 |

|

M3 |

0.5 |

1d/1.5/2d/2.5d/3d |

3.80~4.00 |

3.2 |

|

M4 |

0.7 |

1d/1.5/2d/2.5d/3d |

5.05~5.25 |

4.2 |

|

M5 |

0.8 |

1d/1.5/2d/2.5d/3d |

6.35~6.60 |

5.2 |

|

M6 |

1 |

1d/1.5/2d/2.5d/3d |

7.60~7.85 |

6.3 |

|

M7 |

1 |

1d/1.5/2d/2.5d/3d |

8.65~8.90 |

7.3 |

|

M8 |

1.25 |

1d/1.5/2d/2.5d/3d |

9.85~10.10 |

8.4 |

|

M10 |

1.25 |

1d/1.5/2d/2.5d/3d |

12.10~12.50 |

10.4 |

|

M11 |

1.5 |

1d/1.5/2d/2.5d/3d |

13.10~13.50 |

11.5 |

|

M12 |

1.75 |

1d/1.5/2d/2.5d/3d |

14.40~14.80 |

12.5 |

|

Inch | |||||

2-56 (0.086) |

0.435 |

1d/1.5d/2d/2.5d |

2.7~2.9 |

2.4 |

|

4-40 (0.112) |

0.635 |

1d/1.5d/2d/2.5d |

3.6~4.0 |

3.1 |

|

5-40 (0.125) |

0.635 |

1d/1.5d/2d/2.5d |

4.0~4.4 |

3.4 |

|

6-32 (0.138) |

0.794 |

1d/1.5d/2d/2.5d |

4.5~4.9 |

3.8 |

|

8-32 (0.164) |

0.794 |

1d/1.5d/2d/2.5d |

5.2~5.6 |

4.4 |

|

10-24 (0.190) |

1.058 |

1d/1.5d/2d/2.5d |

6.2~6.6 |

5.2 |

|

12-24 (0.216) |

1.058 |

1d/1.5d/2d/2.5d |

6.8~7.2 |

5.8 |

|

1/4"-20 |

1.27 |

1d/1.5d/2d/2.5d |

8.0~8.4 |

6.7 |

|

5/16"-18 |

1.411 |

1d/1.5d/2d/2.5d |

9.7~10.2 |

8.4 |

|

3/8"-16 |

1.588 |

1d/1.5d/2d/2.5d |

11.5~12.0 |

10 |

|

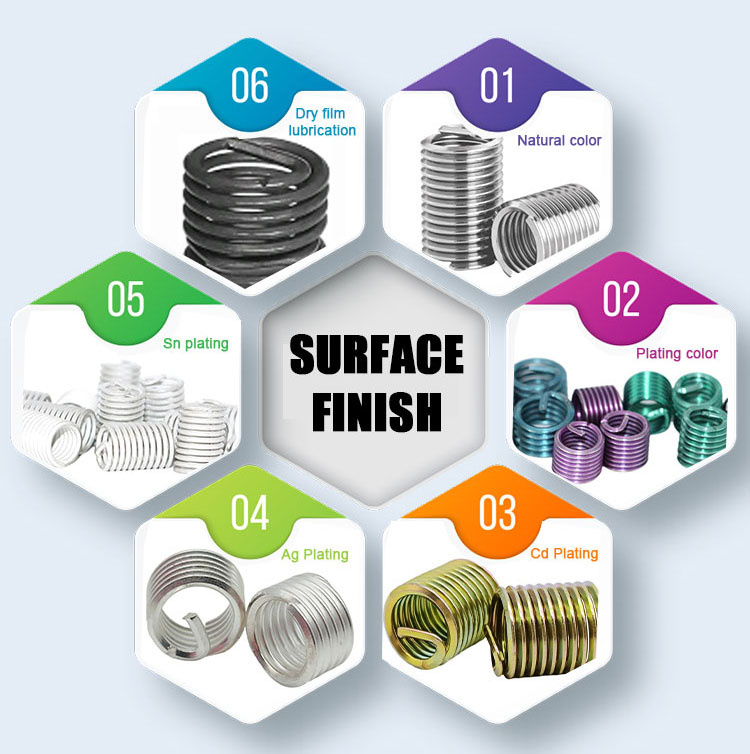

Surface treatment

For steel wire threaded inserts made of 304 stainless steel, the surface treatments available are:

1. No treatment, natural surface

2. Environmentally friendly colour plating, according to customer needs can be plated in purple, green, blue, red. In industries where large quantities of threaded inserts are required, colour plated wire threaded inserts help to identify whether they are installed or not. The different colours of the wire threaded inserts are also very convenient for visual management.

3. Cadmium plating, cadmium (cd) plated steel wire threaded inserts corrosion resistance, lubrication, wear resistance, electrical conductivity, electromagnetic properties, heat resistance is stronger.

4. Silver-plated, silver-plated steel threaded bushings can be installed in a variety of shell materials, including magnesium alloys, aluminium alloys and corrosion and heat-resistant materials, mainly used to reduce the screw threads in the high-temperature state of the bonding effect.

5. Tin-plated, tin-plated steel wire threads inserts have the biggest advantage of better corrosion resistance, for corrosion resistance has high requirements, you can consider tin-plated coating of steel wire threads.

6. Dry film lubrication for mild corrosion or high temperature environment.

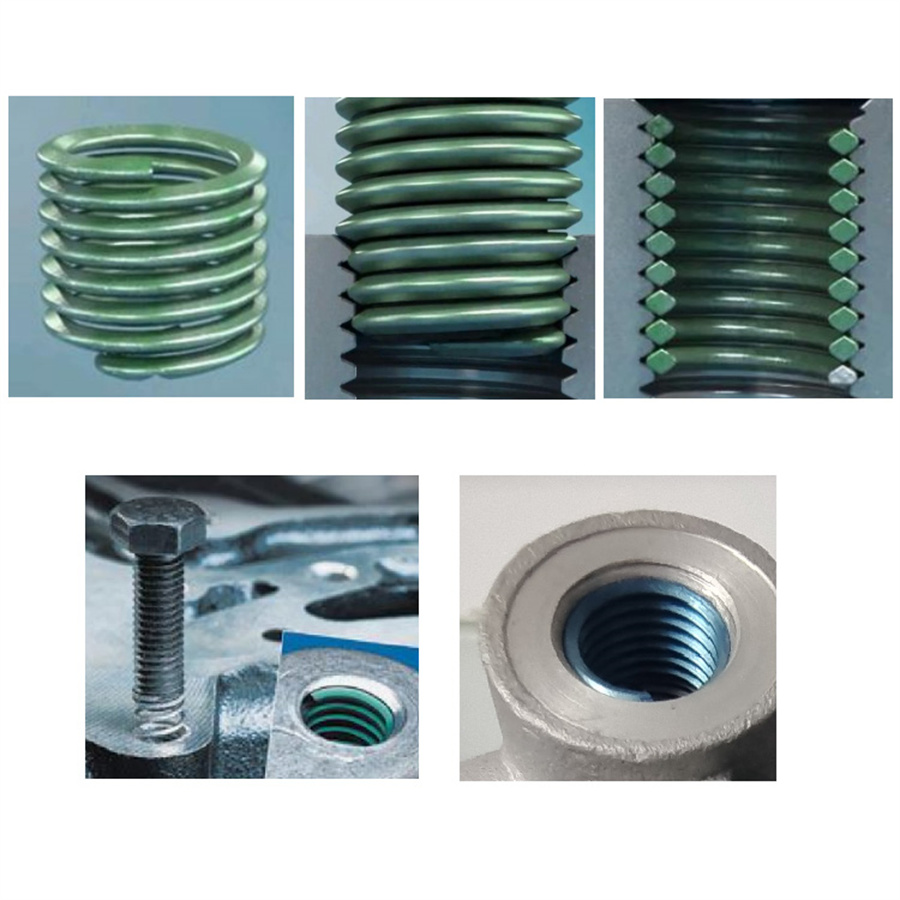

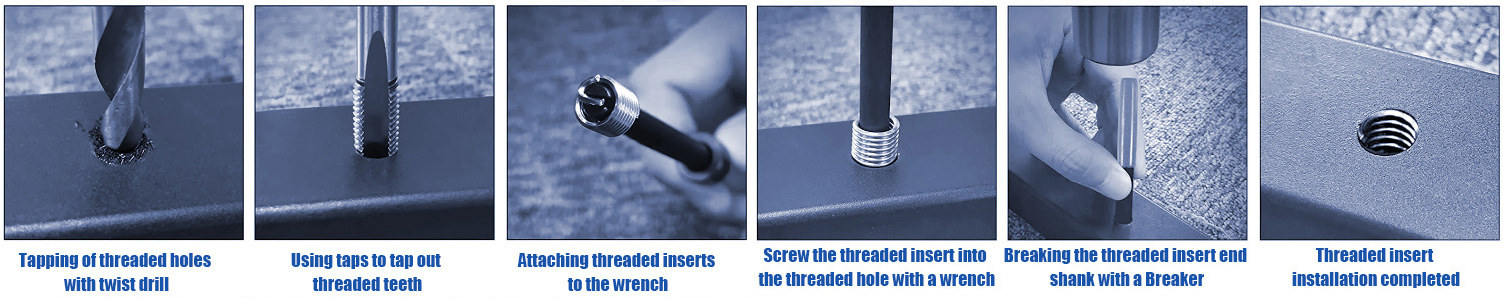

Product Installation Steps

Wire threaded inserts can be installed using either hand tools or power tools. Here are some simple installation procedures using hand tools, if you happen to need them, please take a closer look at it.

1. Drilling

Use a drill bit to drill a bottom hole of the appropriate size. (Please refer to the product documentation for details or contact us for the hole size.)

2.Tapping

Drill the correct size threaded holes using the special taps for Flyaway wire threaded inserts.

3.Installation

Install the wire thread insert into the head of the mounting arbor.

4. Screw into the thread hole

Align the head of the mandrel or tool with the wire threaded insert into the prepared threaded hole and rotate it so that the wire threaded insert enters the bottom hole completely and is slightly below the surface of the workpiece to be installed.

5. Breaking off the tang

Use a shank removal tool to break off the tang of the installed wire threaded insert.

6. Installation completed

Application of wire threaded inserts

AVIC-Flight thread insert provides high strength threads, by means of transferring the stress from flank to flank into the holding thread. A system of high reliability, AVIC-Flight is a guarantee for standardised material and quality requirements for manufactured thread inserts. They are the basis of national standards, aeronautical standards, military standards,and also for in-house standards of leading major users.

■Design Element

Anywhere where materials of low shearing strength are utilised (for example aluminium, alu-magnesium alloys),AVIC-Flight thread insert is indispensable for thread reinforcement. Branches that are especially effected by this are machine and plant construction, the automobile industry, electronic and medicine technology as well as aeronautics and the astronautics industries. By use of the thread reinforcement, wear and tear of the nut thread can be ruled out even with regular functions. AVIC-Flight thread insert makes the development of miniaturisation and lightweight design for volume parts possible.Stability is guaranteed by the use of threading reinforcement with AVIC-Flight thread insert.

■Reject Reclamation and Repairing of Threads

AVIC-Flight thread inserts have been released world-wide for the economical and lasting repairing of

damaged or worn out threads.

Alongside the repair of valuable individual components, the possibility of recycling damaged threads of rejected large production volume component parts, allowing for the feed back into the production process, is of major importance.

Part of the application industry display