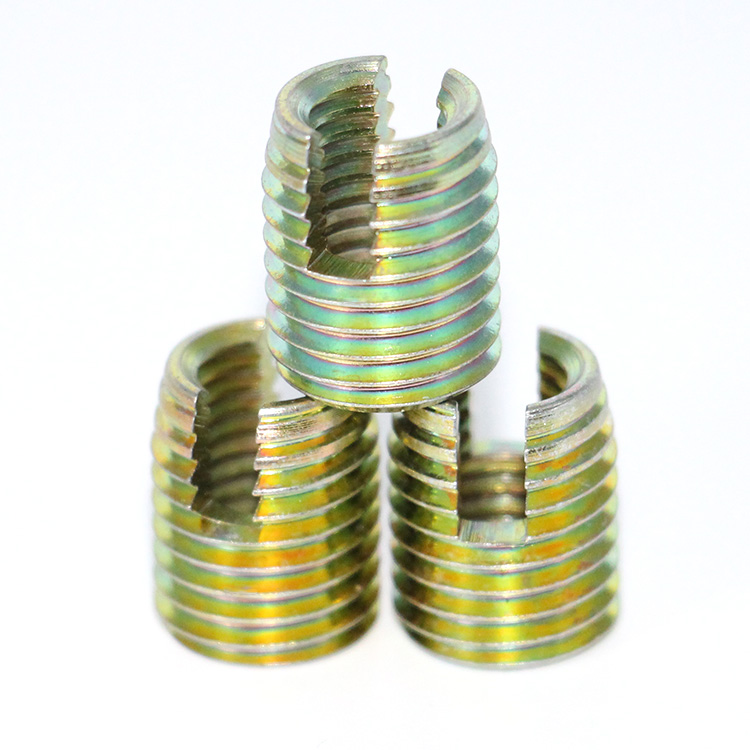

307 series Self tapping cutting thread insert with cutting hole

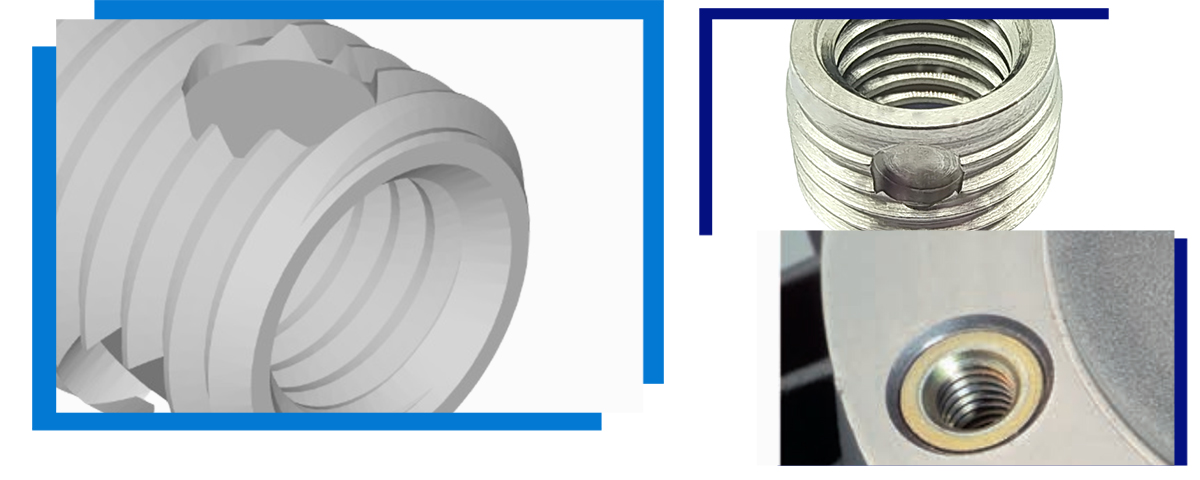

337 series self-tapping thread inserts for blind holes

The 337/338 series is specially designed for use in situations where the cutting is not allowed to fall into the hole, so the three cutting holes are blind holes. For flanges the code name is 337/338H. If the bottom end is closed, the code 357/358 is used.

Features of self tapping thread insert:

1. The self tapping thread insert has the ability of self tapping and automatic chip removal, and the base material does not need to be pre tapped.

2. The self tapping thread insert has a large contact surface with the finished product and can withstand strong tensile force. Low strength materials can be used in product design.

3. The self tapping screw insert has a repairing effect on the mother thread of the broken tooth, and using a slotted self tapping screw insert can continue to use the same screw

4. The self tapping thread insert has excellent airtightness and shock resistance, which can prevent loosening and improve the connection strength with the base material.

5. The self tapping thread insert installation is simple and fast, requiring only one assembly tool, with low cost and almost no defect rate.

Features of self tapping thread insert

|

Product name |

337 series Self tapping thread insert |

|

Material |

Steel Zn/SUS303/Customized |

|

Surface color |

Galvanized/Natural color |

|

Galvanizing: yellow/blue/Colored |

|

|

Thread type |

Metric,Inc UNC, UNF |

|

Model Number |

M3-M24/Customized |

|

Function |

Assembly, threaded connection/fastening/conversion |

|

Reliability test |

Mechanical dimentions, hardness test. salt spray endurance test |

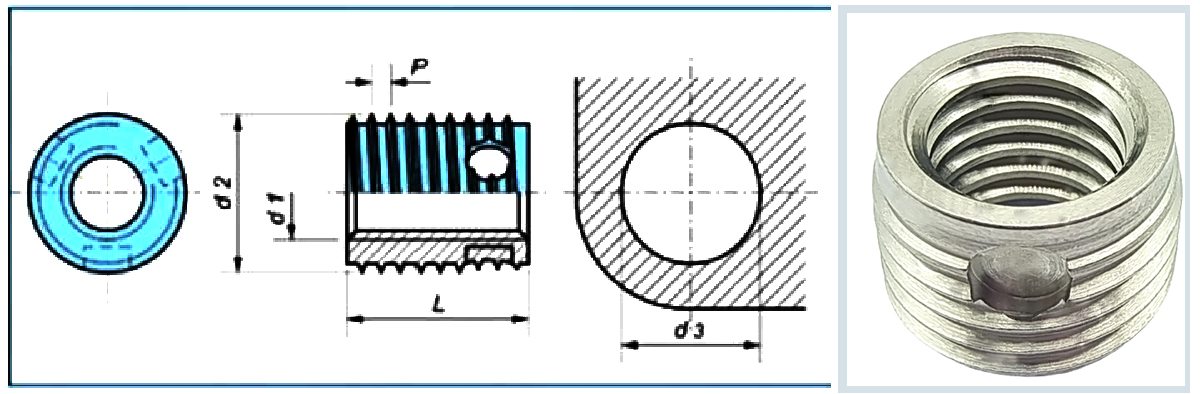

Table of dimensions for 337 series self-tapping threaded inserts

|

Model number |

Metric Thread |

External Thread |

Total Length |

APPROX HOLE DIAMETER |

Mine Hole Depth |

|||

|

d1 |

d2 |

P |

L |

Light alloy RM<250 C.Iron<150HB Plastic |

Light alloy RM <350 C.Iron<200HB Hand Plastic |

Light Alloy RM>350 C.Iron >200HB Brass |

||

|

3370030... |

M3 |

5 |

6 |

4 |

4,6-4,7 |

4,7-4,7 |

4,7-4,8 |

6 |

|

3380030... |

6 |

8 |

||||||

|

3370035... |

M3.5 |

6 |

8 |

5 |

5,5-5,6 |

5,6-5,6 |

5,6-5,7 |

7 |

|

3380035... |

8 |

10 |

||||||

|

3370040... |

M4 |

65 |

8 |

6 |

6,0-6,1 |

6,1-6,1 |

6,1-6,2 |

8 |

|

3380040... |

8 |

10 |

||||||

|

3370050... |

M5 |

8 |

1 |

7 |

7,4-7,5 |

7,5-7,6 |

7.6-7,7 |

9 |

|

3380050... |

10 |

13 |

||||||

|

3370060... |

M6 |

10 |

125 |

8 |

9,3-9,4 |

9,4-9,5 |

9,5-9,6 |

10 |

|

3380060... |

12 |

15 |

||||||

|

3370080... |

M 8 |

12 |

15 |

9 |

11,1-11,2 |

11,2-11,3 |

11,3-11,5 |

11 |

|

3380080... |

14 |

17 |

||||||

|

3370100... |

M 10 |

14 |

15 |

10 |

13,1-13,2 |

13,2-13.3 |

13.3-13,5 |

13 |

|

3380100... |

18 |

22 |

||||||

|

3370120... |

M 12 |

16 |

175 |

12 |

15,0-15,1 |

15,1-15,2 |

15.2-15,4 |

15 |

|

3380120... |

22 |

26 |

||||||

|

3370140... |

M14 |

18 |

2 |

14 |

17,0-17,1 |

17,1-17,2 |

17,2-17,4 |

17 |

|

3380140... |

24 |

28 |

||||||

|

3370160... |

M 16 |

20 |

2 |

14 |

19,0-19,1 |

19,1-19,2 |

19,2-19,4 |

17 |

Example for finding the article number:Self-tapping threaded insert FH to Works Standard 302 1 with internal thread A = M5 made of case-hardened , zinc plated and blue passivated steel : 307.000.050.110

Tolerance:ISO 2768-m

Thread:

Internal thread A: as per ISO 6H

External thread E: as per FH standard

Materials

|

Article no. (fourth group of digits)... ... ...110 |

Article no. (fourth group of digits)... ... ...110 |

|

Case-hardened steel, Zinc-nickel plated, transparent passivated |

Article no. (fourth group of digits)... ... ...143 |

|

Case-hardened steel , Zinc plated , yellow chromated |

Article no. (fourth group of digits)... ... ...160

|

|

Stainless steel 14301 |

Article no. (fourth group of digits)... ... ...400 |

|

Stainless steel 14305 |

Article no. (fourth group of digits)... ... ...500 |

|

Stainless steel 14401 |

Article no. (fourth group of digits)... ... ...600 |

|

Ti 3.7035 |

Article no. (fourth group of digits)... ... ...700 |

|

Brass

|

Article no. (fourth group of digits)... ... ...800

|

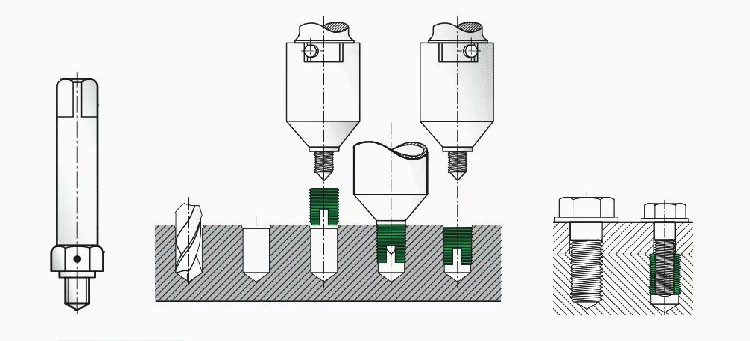

Product Installation Steps

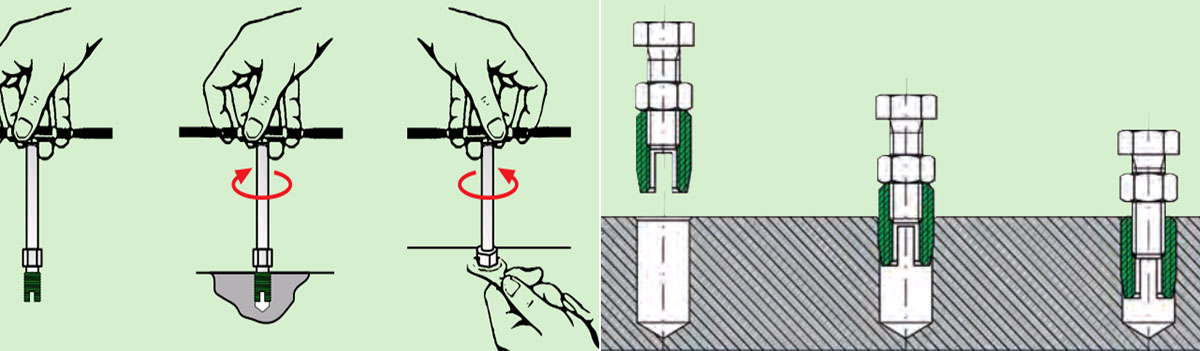

Manual Installation:

Use the special thread insert installation tool. Refer to the figure below for the specific operation method. The end of the tool in the figure is a quadrangle head which can be connected with a manual tapping wrench.

Electric Installation:

1. Position the workpiece exactly,so that drilling and machines -spindle axially parallel to each other lie (do not tilt).Machine to the exact screwing depth adjust (approx. 0.1 to 0.2 mm under the workpiece surface ).

2. Machine operating lever actuate. When you start screwing in, the rota table outer sleeve of the tool must be in line with what is visible on the outside stop pins so that they of these clockwise with -is taken.

3. Add Self tapping thread insert to the tool (Slot or cutting hole according to bottom) and 2 to 4 turns hold on for a long time.

4. Machine operating lever continue to operate and take the tool with you Guide Self tapping thread insert to the hole until the Self tapping thread insert gets into the borehole cuts in. The further turning takes place without feed actuation.

5. Switch on reverse (depending on type and the device is constructed

this automatically using a limit switch or depth finder).

Hard landing

of the tool onto the workpiece avoid at all costs; otherwise exists

Risk of breakage for tools and Self tapping thread insert. In addition, The play-free tight fit of the Self tapping thread insert is destroyed and the pull-out strength is reduced. The screwing speed may need to be adjusted to the required speed Switchover time can be adjusted.