0102030405

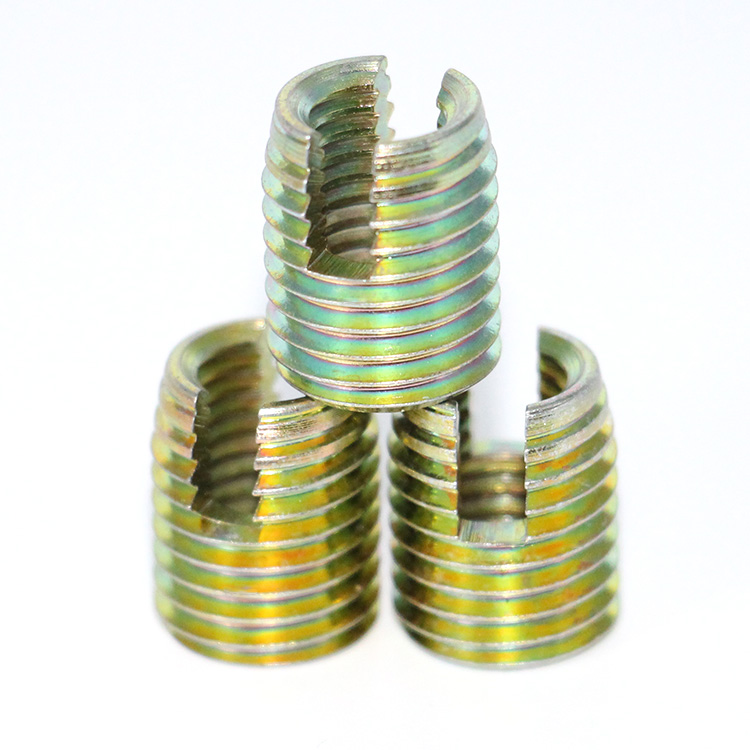

309 Series self tapping wood inserts nut for wood

309 Series self tapping wood inserts nut for wood

Self-tapping thread insert does not need to tap teeth in advance when installing, so it is called self-tapping thread insert. 309 series is a kind of self-tapping thread insert, the main materials are stainless steel and carbon steel and brass.

309 series self-tapping thread insert in the international many applications in the wood products industry

Feature

◆Provides strong female threads on soft substrates to accommodate multiple repairs and disassembly needs;

◆Can effectively repair damaged internal threads;

◆Self-tapping sleeves are used after die casting, injection molding, or other manufacturing processes, so they allow for simplified product mix and improved yields;

◆Self-tapping bushings can withstand high loads, so smaller inserts can be used, resulting in a more compact product design.

Self tapping thread insert parameter

| Product name | 309 type Self tapping thread insert |

| Material | Brass/stainless steel/carbon steel |

| Thread type | Metric |

| Model Number | M2-M16/Customized |

| Function | Assembly, threaded connection/fastening/conversion |

| Reliability test | Mechanical dimentions, hardness test. salt spray endurance test |

Table of dimensions for 309 series self-tapping threaded inserts

| CODE |

METRIC THREAD |

SPECIAL EXTERNAL THREAD |

TOTAL LENGHT |

APPROX HOLE DIAMETER d3 |

MIN.HOLE DEPTH |

||

|

d1 |

d2 |

P |

L |

Soft Material |

Hard Material |

||

| 3090025.80--- |

M 2.5 |

5 |

1.6 |

6 |

3.5 |

3.6-3.8 |

8 |

| 3090030.80--- |

M 3 |

5.5 |

1.6 |

6 |

4.1 |

4.2-4.3 |

9 |

| 3090035.80--- |

M 3.5 |

6.5 |

1.6 |

8 |

4.6 |

4.7 -4.8 |

10 |

| 3090040.80--- |

M 4 |

7 |

2.5 |

10 |

5.1 |

5.2-5.3 |

13 |

| 3090050.80--- |

M 5 |

9 |

3 |

12 |

6.6 |

6.7-6.9 |

15 |

| 3090060.80--- |

M 6 |

10 |

4 |

14 |

7.6 |

7.7-7.9 |

17 |

| 3090080.80--- |

M 8 |

13 |

4 |

20 |

9.9 |

10.1 -10.3 |

23 |

| 3090100.80--- |

M 10 |

16 |

5 |

23 |

12.4 |

12.6-12.8 |

26 |

| 3090120.80--- |

M 12 |

19 |

5 |

26 |

15.4 |

15.6-15.8 |

30 |

| 3090140.80--- |

M 14 |

22 |

5 |

26 |

18.4 |

18.6-18.8 |

30 |

| 3090160.80--- |

M 16 |

24 |

5 |

26 |

20.4 |

20.6-20.8 |

30 |

Product Installation Steps

Manual Installation:

Use the special thread insert installation tool. Refer to the figure below for the specific operation method. The end of the tool in the figure is a quadrangle head which can be connected with a manual tapping wrench.

The Dill type of HRT numerical control suspension thread insert electric installation machine designed by AVIC can complete the installation of thread insert with high efficiency and high quality.

1. For different processing materials, refer to the drilling size specification for pre-drilling processing. When the hardness of the corresponding material is high, please slightly increase the bottom hole within the drilling range.

2. With the slotted end of the socket down, install the self-tapping thread insert completely into the front of the tool, and it should be in vertical contact with the work piece. When installing (1 to 2 pitches), please make sure that the bottom hole is aligned and never tilt. If tilting is detected, do not reverse the tool and readjust before using. After 1/3 to 1/2 of the way in, do not start again. In addition, please do not reverse the rotation of the tool, otherwise it will cause product failure.

3. The self-tapping thread insert should be at least 1mm below the surface of the part after assembly.