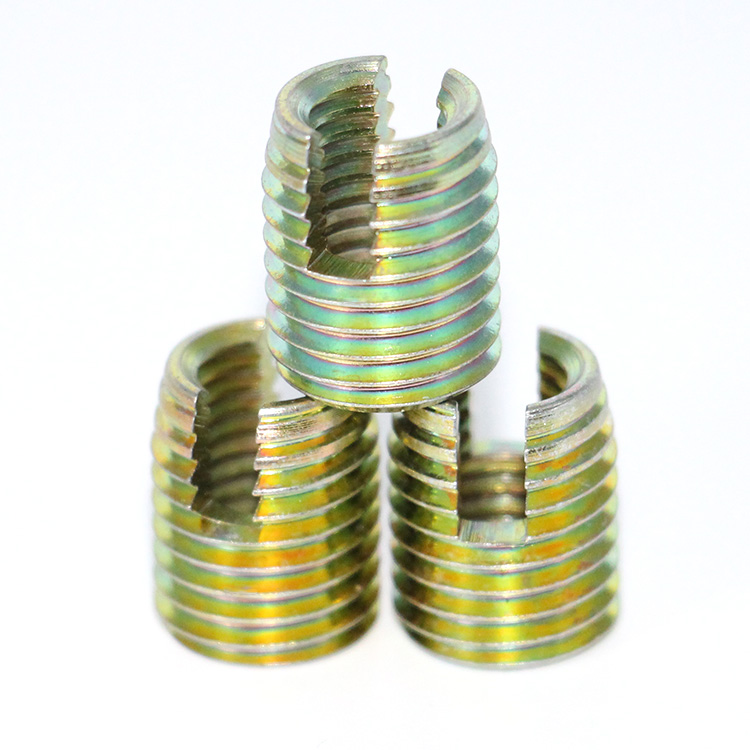

Black galvanized stainless steel wire threaded insert

Black galvanized stainless steel wire threaded insert

The wire thread insert is made of high-quality austenitic stainless steel material. It forms a reliable internal thread after installation and embedding. It can significantly improve the strength and safety of low-strength engineering materials such as aluminum, magnesium, copper alloy, plastic, plexiglass, and bakelite. Wear resistance; applied to steel parts, cast steel, and cast iron, it can improve the durability of screws, prevent screws from loosening and falling off, fatigue fracture due to various vibrations, and improve the fatigue resistance of screws during connection. The advantages of wire thread inserts are: high wear resistance and tensile strength, low thread friction, high surface quality, and excellent anti-corrosion and heat resistance.

Galvanized steel wire thread inserts are steel wire thread inserts made of stainless steel wire, but with a zinc coating on the surface, which improves the corrosion resistance and appearance of the steel wire thread insert.

The role of surface galvanizing

The main purpose of zinc plating on stainless steel surfaces is to improve their corrosion resistance and aesthetics. Zinc plating forms a protective layer of zinc-iron alloy on the stainless steel surface, effectively preventing the stainless steel from coming into contact with oxygen, water, etc. in the external environment, thus preventing rusting. In addition, zinc plating can also increase the aesthetics of stainless steel, making its surface smoother and increasing its reflective properties, thus enhancing its decorative effect. This treatment not only improves the durability of stainless steel but also extends its service life, especially in harsh environmental conditions.

Wire Thread Insert Parameters

Product name |

Wire thread insert |

Material |

SUS304/SUS316/SUS321/InX750/Brass/Customized |

Surface color |

None / Eco-friendly plating |

Surface coating |

Silver/tin/cadmium/zinc/other |

Thread type |

Metric,Inc UNC, UNF |

Metric Size |

M1.4*0.3P~M85*6.0P |

Inch UNC Size |

1-64~11/2“-6 |

Inch UNF Size |

4-48~11/2“-12 |

Production standard |

MS21209/DIN8140/N926/ITN32760/MO-44421 |

Diameter |

Pitch |

d |

(Dz) |

Bit diameter |

|

(d) |

(P) |

|

|

(do) |

|

Metric | |||||

M1.6 |

0.35 |

1d/1.5/2d/2.5d/3d |

2.08-2.18 |

1.7 |

|

M2 |

0.4 |

1d/1.5/2d/2.5d/3d |

2.60~2.80 |

2.1 |

|

M2.5 |

0.45 |

1d/1.5/2d/2.5d/3d |

3.30~3.50 |

2.6 |

|

M3 |

0.5 |

1d/1.5/2d/2.5d/3d |

3.80~4.00 |

3.2 |

|

M4 |

0.7 |

1d/1.5/2d/2.5d/3d |

5.05~5.25 |

4.2 |

|

M5 |

0.8 |

1d/1.5/2d/2.5d/3d |

6.35~6.60 |

5.2 |

|

M6 |

1 |

1d/1.5/2d/2.5d/3d |

7.60~7.85 |

6.3 |

|

M7 |

1 |

1d/1.5/2d/2.5d/3d |

8.65~8.90 |

7.3 |

|

M8 |

1.25 |

1d/1.5/2d/2.5d/3d |

9.85~10.10 |

8.4 |

|

M10 |

1.25 |

1d/1.5/2d/2.5d/3d |

12.10~12.50 |

10.4 |

|

M11 |

1.5 |

1d/1.5/2d/2.5d/3d |

13.10~13.50 |

11.5 |

|

M12 |

1.75 |

1d/1.5/2d/2.5d/3d |

14.40~14.80 |

12.5 |

|

Inch | |||||

2-56 (0.086) |

0.435 |

1d/1.5d/2d/2.5d |

2.7~2.9 |

2.4 |

|

4-40 (0.112) |

0.635 |

1d/1.5d/2d/2.5d |

3.6~4.0 |

3.1 |

|

5-40 (0.125) |

0.635 |

1d/1.5d/2d/2.5d |

4.0~4.4 |

3.4 |

|

6-32 (0.138) |

0.794 |

1d/1.5d/2d/2.5d |

4.5~4.9 |

3.8 |

|

8-32 (0.164) |

0.794 |

1d/1.5d/2d/2.5d |

5.2~5.6 |

4.4 |

|

10-24 (0.190) |

1.058 |

1d/1.5d/2d/2.5d |

6.2~6.6 |

5.2 |

|

12-24 (0.216) |

1.058 |

1d/1.5d/2d/2.5d |

6.8~7.2 |

5.8 |

|

1/4"-20 |

1.27 |

1d/1.5d/2d/2.5d |

8.0~8.4 |

6.7 |

|

5/16"-18 |

1.411 |

1d/1.5d/2d/2.5d |

9.7~10.2 |

8.4 |

|

3/8"-16 |

1.588 |

1d/1.5d/2d/2.5d |

11.5~12.0 |

10 |

|

Other surface treatment methods for wire thread inserts

For steel wire threaded inserts made of 304 stainless steel, the surface treatments available are:

1. No treatment, natural surface

2. Environmentally friendly colour plating, according to customer needs can be plated in purple, green, blue, red. In industries where large quantities of threaded inserts are required, colour plated wire threaded inserts help to identify whether they are installed or not. The different colors of the wire threaded inserts are also very convenient for visual management.

3. Cadmium plating, cadmium (cd) plated steel wire threaded inserts corrosion resistance, lubrication, wear resistance, electrical conductivity, electromagnetic properties, heat resistance is stronger.

4. Silver-plated, silver-plated steel threaded bushings can be installed in a variety of shell materials, including magnesium alloys, aluminium alloys and corrosion and heat-resistant materials, mainly used to reduce the screw threads in the high-temperature state of the bonding effect.

5. Tin-plated, tin-plated steel wire threads inserts have the biggest advantage of better corrosion resistance, for corrosion resistance has high requirements, you can consider tin-plated coating of steel wire threads.

6. Dry film lubrication for mild corrosion or high temperature environment.