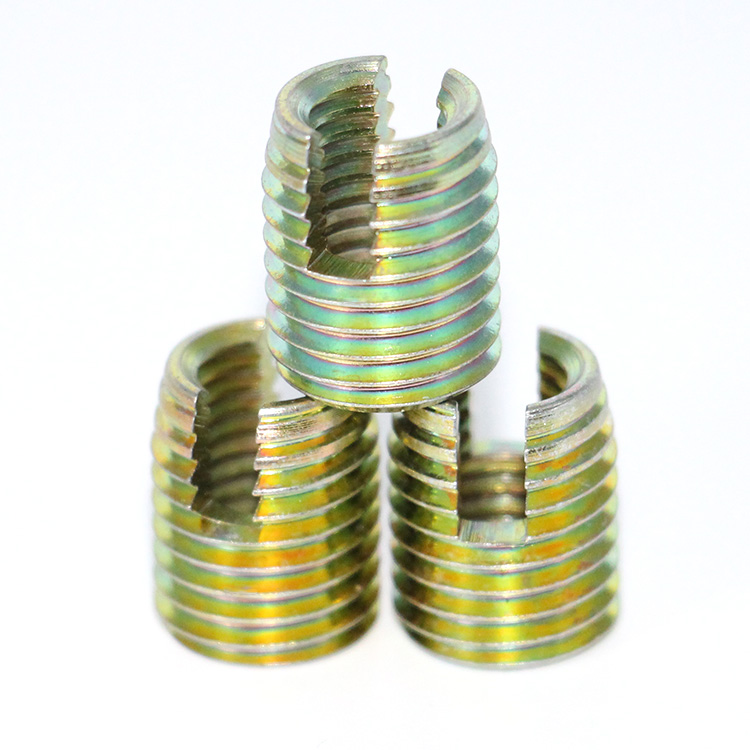

Environmentally friendly coating purple wire thread insert

Environmentally friendly coating purple wire thread insert

For wire thread inserts, 304 stainless steel is the most widely used material. In addition, wire thread inserts can also be produced in 316 stainless steel, 321 stainless steel, InX750, brass and other materials according to customer needs.

The most commonly used material, 304 stainless steel, can also be subjected to different forms of surface treatment.

The surface of the steel wire thread insert purple environmental protection coating treatment is one of the ways.

Colored steel wire thread inserts, steel wire thread inserts are usually in their natural stainless steel color, but may be colored for specific applications. Colored steel wire thread inserts are widely used in large-volume, multi-variety installations.

Advantages of colored steel wire thread inserts:

1. Colored steel wire thread inserts are used to distinguish between different specifications and applications of thread insert products, making inventory management easier.

2. After colored steel wire thread inserts are installed, they form a distinct color contrast with the base material of the cast aluminum workpiece, making it easier to check whether the thread insert was installed properly and whether it was installed correctly or not after assembly.

Wire Thread Insert Parameters

Product name |

Wire thread insert |

Material |

SUS304/SUS316/SUS321/InX750/Brass/Customized |

Surface color |

None / Eco-friendly plating |

Surface coating |

Silver/tin/cadmium/zinc/other |

Thread type |

Metric,Inc UNC, UNF |

Metric Size |

M1.4*0.3P~M85*6.0P |

Inch UNC Size |

1-64~11/2“-6 |

Inch UNF Size |

4-48~11/2“-12 |

Production standard |

MS21209/DIN8140/N926/ITN32760/MO-44421 |

Other surface treatments for wire threaded inserts

For steel wire threaded inserts made of 304 stainless steel, the surface treatments available are:

1. No treatment, natural surface

2. Environmentally friendly colour plating, according to customer needs can be plated in purple, green, blue, red. In industries where large quantities of threaded inserts are required, colour plated wire threaded inserts help to identify whether they are installed or not. The different colours of the wire threaded inserts are also very convenient for visual management.

3. Cadmium plating, cadmium (cd) plated steel wire threaded inserts corrosion resistance, lubrication, wear resistance, electrical conductivity, electromagnetic properties, heat resistance is stronger.

4. Silver-plated, silver-plated steel threaded bushings can be installed in a variety of shell materials, including magnesium alloys, aluminium alloys and corrosion and heat-resistant materials, mainly used to reduce the screw threads in the high-temperature state of the bonding effect.

5. Tin-plated, tin-plated steel wire threads inserts have the biggest advantage of better corrosion resistance, for corrosion resistance has high requirements, you can consider tin-plated coating of steel wire threads.

6. Dry film lubrication for mild corrosion or high temperature environment.

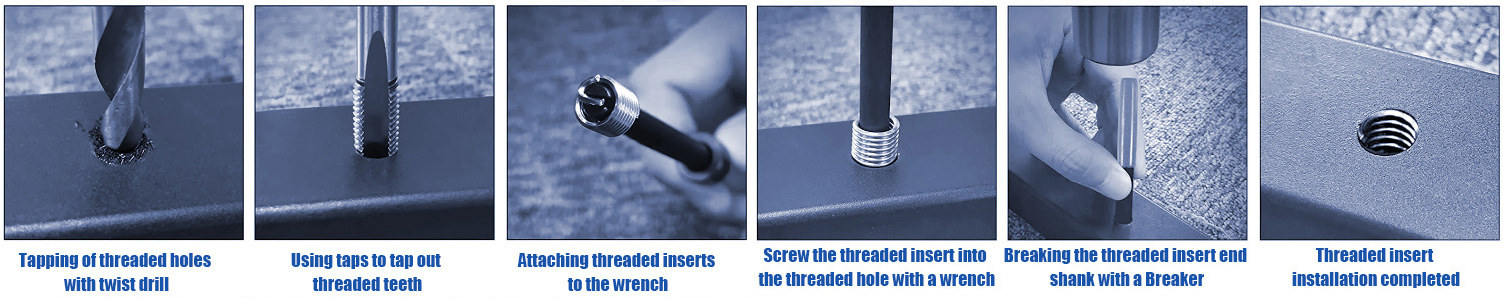

Product Installation Steps of wire thread insert

Wire threaded inserts can be installed using either hand tools or power tools. Here are some simple installation procedures using hand tools, if you happen to need them, please take a closer look at it.

1. Drill holes

2. Use a special tap to screw into the drilled hole to form a threaded hole

3. Using a special installation wrench, first put the threaded insert into the head of the installation tool.

4. Then align the head of the tool with the threaded insert with the threaded hole and rotate to screw the threaded insert in.

5. Remove the shank with the shank remover tool.

6. Successful installation