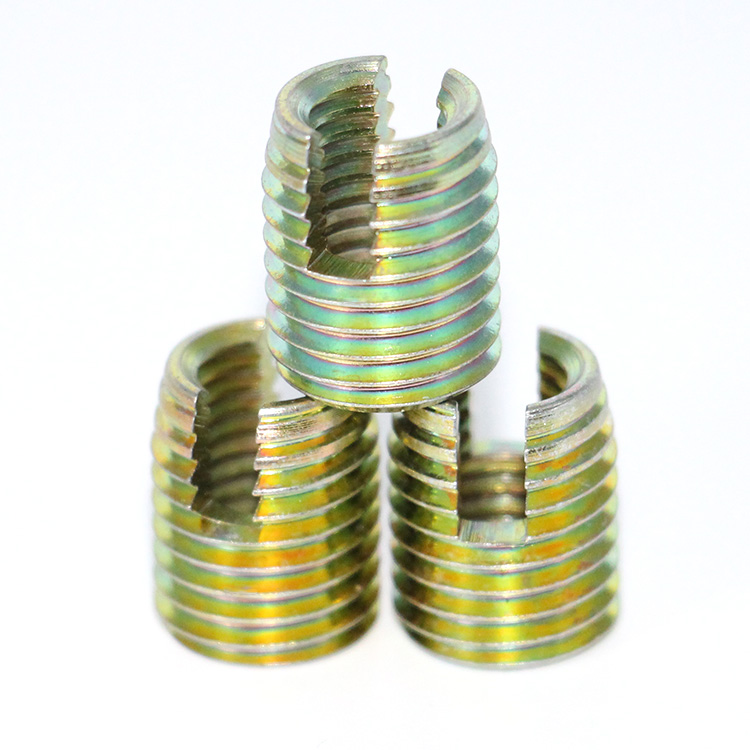

Locking type screw-lock wire thread insert

Locking type screw-lock wire thread insert

Locking type wire thread insert is a new type developed on the basis of the original common type wire thread insert. Locking type wire thread insert middle part of 1 to 2 turns of pentagonal or hexagonal, when the bolt is screwed into the threaded hole half, the bolt head touches the locking ring, this time through the tool to apply the force of the steel wire thread insert than the other some of the usual locking device locking performance is more superior, higher strength, but also can be repeatedly disassembled.

When the screw screwed into the locking type wire screw holes, in the polygon before the locking ring is loose, when the screw into the polygon of the locking ring, the polygon needs to be supported, so that the locking side of the deformation, the screw screwed into the need to overcome the locking side of the friction given to the screw. Screws tightened after this friction can make the screw will not be released, thus replacing other locking methods.

Wire Thread Insert Parameters

Product name |

Screw-lock wire thread insert |

Material |

SUS304/SUS316/SUS321/InX750/Brass/Customized |

Surface color |

None / Eco-friendly plating |

Surface coating |

Silver/tin/cadmium/zinc/other |

Thread type |

Metric,Inc UNC, UNF |

Metric Size |

M1.4*0.3P~M85*6.0P |

Inch UNC Size |

1-64~11/2“-6 |

Inch UNF Size |

4-48~11/2“-12 |

Production standard |

MS21209/DIN8140/N926/ITN32760/MO-44421 |

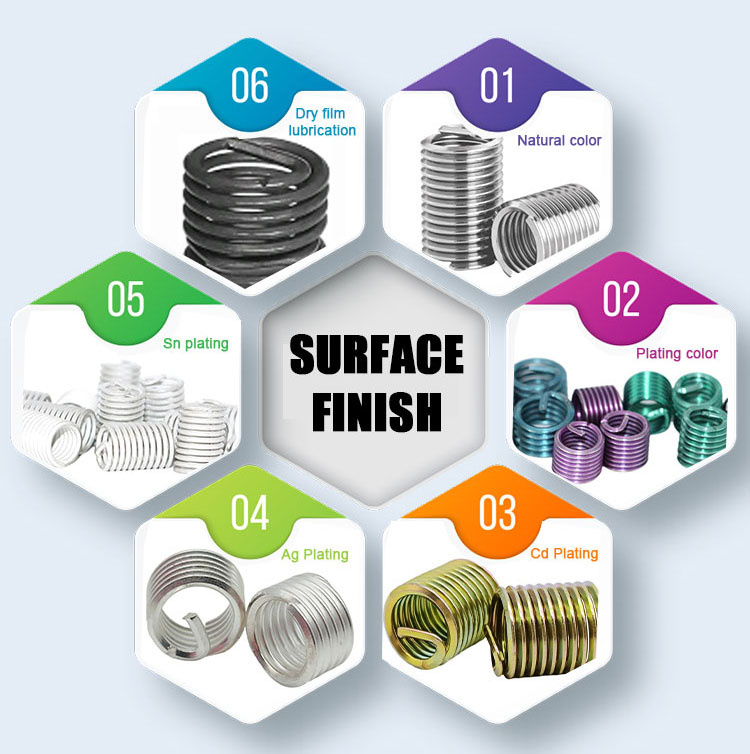

Surface treatment

For steel wire threaded inserts made of 304 stainless steel, the surface treatments available are:

1. No treatment, natural surface

2. Environmentally friendly colour plating, according to customer needs can be plated in purple, green, blue, red. In industries where large quantities of threaded inserts are required, colour plated wire threaded inserts help to identify whether they are installed or not. The different colours of the wire threaded inserts are also very convenient for visual management.

3. Cadmium plating, cadmium (cd) plated steel wire threaded inserts corrosion resistance, lubrication, wear resistance, electrical conductivity, electromagnetic properties, heat resistance is stronger.

4. Silver-plated, silver-plated steel threaded bushings can be installed in a variety of shell materials, including magnesium alloys, aluminium alloys and corrosion and heat-resistant materials, mainly used to reduce the screw threads in the high-temperature state of the bonding effect.

5. Tin-plated, tin-plated steel wire threads inserts have the biggest advantage of better corrosion resistance, for corrosion resistance has high requirements, you can consider tin-plated coating of steel wire threads.

6.Dry film lubrication for mild corrosion or high temperature environment.

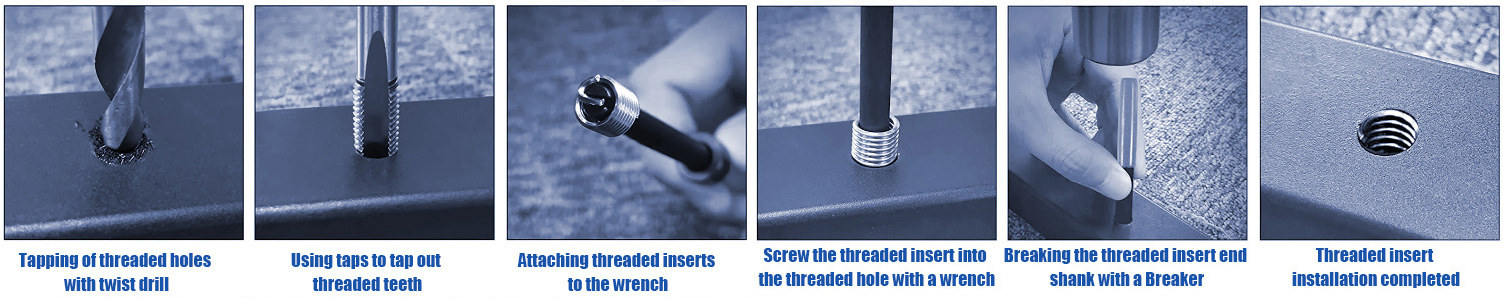

Product Installation Steps

The installation procedure for locking wire thread inserts is the same as that for normal wire thread inserts.

Wire threaded inserts can be installed using either hand tools or power tools. Here are some simple installation procedures using hand tools, if you happen to need them, please take a closer look at it.

1. Drill holes

2. Use a special tap to screw into the drilled hole to form a threaded hole

3. Using a special installation wrench, first put the threaded insert into the head of the installation tool.

4. Then align the head of the tool with the threaded insert with the threaded hole and rotate to screw the threaded insert in.

5. Remove the shank with the shank remover tool.

6. Successful installation

Application of wire threaded inserts

1.Assembly <Improve the performance of internal thread connection>:

Embed the steel wire thread insert on metal or non-metallic materials to form a high strength, wear-resistant, interchangeable standard internal thread. Applied to aluminium, magnesium, copper alloy, plastic, organic glass, plywood and other low-strength engineering materials, it can significantly improve the strength and wear resistance; applied to steel, cast steel, cast iron, it can improve the durability of the screw , prevent the screw from loosening due to a variety of vibrations caused by the screw to fall, fatigue rupture and to improve the fatigue strength of the screw in the connection.

2.Conversion <metric and imperial thread conversion>:

the use of steel wire thread insert for metric ← → inch system ← → international standard threaded hole conversion, very convenient, fast, economical, practical, applicable to any import and export products.

3.Repair <internal thread repair>:

In the event of thread processing errors or repair of damaged internal threaded holes, the use of steel wire threaded bushings as a means of repair can be obtained without increasing the weight and volume of the repair economically to save the important parts, fast and effective repair to the original state, while also meeting or exceeding the original technical requirements.

Part of the application industry display