Self locking Key locking thread insert

Self locking Key locking thread insert

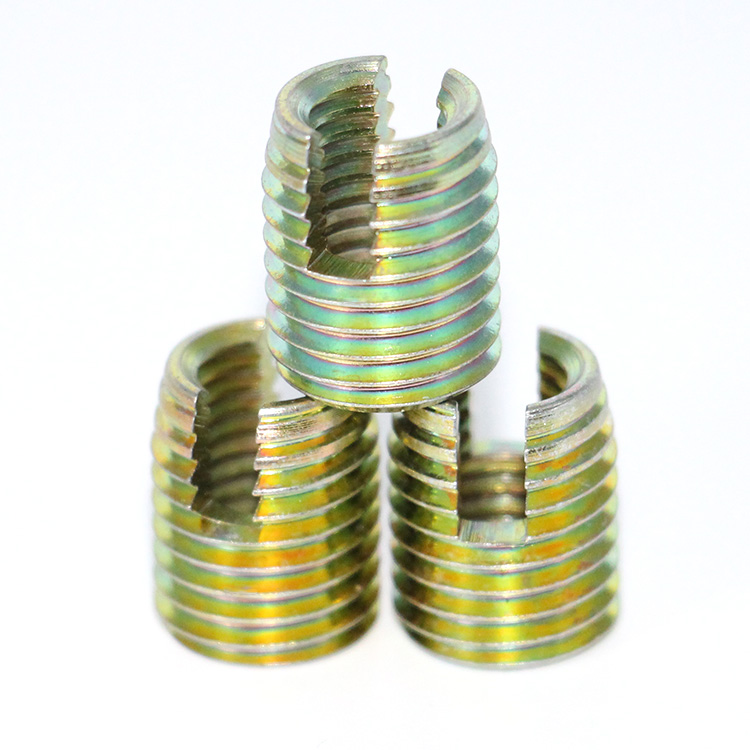

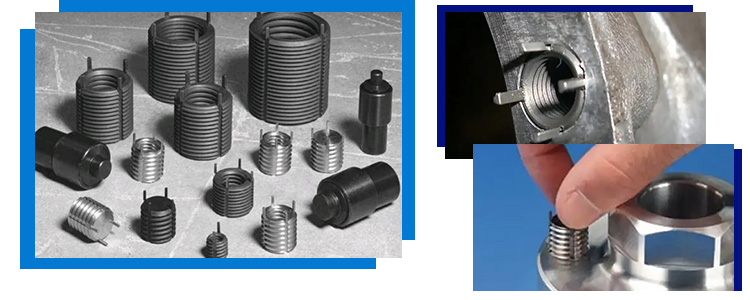

Key locking thread insert is a high-strength fastener, which is installed in the thread hole, can provide a very reliable high-strength internal thread, can provide high strength wear resistance and tensile load of the internal thread hole, there are 2 or 4 bolt keys on the external thread of the key locking thread insert, the key locking thread insert is installed into the thread hole, press into the bolt key, the Key locking thread insert can be firmly locked in the material thread hole.

Self locking Key locking thread insert

According to the shape and structure of the Key locking thread insert, the key locking thread insert be divided into two types: normal type and locking type. The locking effect of the key lock thread insert is excellent and its key pin can fix it on the installed object. It is especially suitable for high-intensity vibration environment and can effectively resist earthquakes

On the basis of the none-locking type key locking insert, a locking slot is designed for the self-locking key locking insert, which makes its performance more superior.Self Locking type key locking insert, which has better shock resistance, more tight after installation

Key locking Thread Insert Parameters

Product name |

Key locking thread insert |

Finish |

Passivated |

Surface color |

None / Black anodised (carbon steel) |

Tolerances |

±.010 inch unless specified otherwise |

Internal Threads |

Per SAE AS8879 |

Dimensions |

All dimensions below are in inches |

Keys |

Inserts with an internal thread size of 5/16 and larger are furnished with 4 locking keys. Smaller sizes have 2 locking keys. |

Material Identification Mark |

None |

Lubrication |

Dry Film Lube on Self-locking Inserts only |

Performance |

MIL-I-45914A(MS51830&NAS1394) |

Metric size -Thin wall key locking thread insert | |||||||

|

Internal Thread

|

External Thread |

Length (mm) |

Tap Drill (mm) |

Thread Tap (mm) |

Tap Depth (mm) |

Removal Dril (mm) |

Removal Depth (mm) |

M5×0.8 |

M8×1.25 |

8.0 |

6.9 |

M8×1.25 |

9.5 |

5.50 |

4.00 |

M6×1.0 |

M10×1.25 |

10.0 |

8.8 |

M10×1.25 |

11.5 |

7.50 |

4.75 |

M8×1.25 |

M12×1.25 |

12.0 |

10.8 |

M12×1.25 |

13.5 |

9.50 |

4.75 |

M8×1.0 |

M12×1.25 |

12.0 |

10.8 |

M12×1.25 |

13.5 |

9.50 |

4.75 |

M10×1.5 |

M14×1.5 |

14.0 |

12.8 |

M14×1.5 |

15.5 |

11.50 |

4.75 |

M10×1.25 |

M14×1.5 |

14.0 |

12.8 |

M14×1.5 |

15.5 |

11.50 |

4.75 |

M12×1.75 |

M16×1.5 |

16.0 |

14.75 |

M16×1.5 |

17.5 |

13.50 |

4.75 |

M12×1.25 |

M16×1.5 |

16.0 |

14.75 |

M16×1.5 |

17.5 |

13.50 |

4.75 |

Metric size -Heavy duty key locking thread insert | |||||||

|

Internal Thread

|

External Thread |

Length (mm) |

Tap Drill (mm) |

Thread Tap (mm) |

Tap Depth (mm) |

Removal Dril (mm) |

Removal Depth (mm) |

M4×0.7 |

M8×1.25 |

8.0 |

6.9 |

M8×1.25 |

9.5 |

5.50 |

4.00 |

M5×0.8 |

M10×1.25 |

10.0 |

8.8 |

M10×1.25 |

12.5 |

7.50 |

4.75 |

M6×1.0 |

M12×1.25 |

12.0 |

10.8 |

M12×1.25 |

14.5 |

9.50 |

4.75 |

M8×1.25 |

M14×1.5 |

14.0 |

12.8 |

M14×1.5 |

16.5 |

11.50 |

4.75 |

M8×1.0 |

M14×1.5 |

14.0 |

12.8 |

M14×1.5 |

16.5 |

11.50 |

4.75 |

M10×1.5 |

M16×1.5 |

16.0 |

14.75 |

M16×1.5 |

18.5 |

13.50 |

4.75 |

M10×1.25 |

M16×1.5 |

16.0 |

14.75 |

M16×1.5 |

18.5 |

13.50 |

4.75 |

M12×1.75 |

M18×1.5 |

18.0 |

16.75 |

M18×1.5 |

20.5 |

15.50 |

4.75 |

M12×1.25 |

M18×1.5 |

18.0 |

16.75 |

M18×1.5 |

20.5 |

15.50 |

4.75 |

M14×2.0 |

M20×1.5 |

20.0 |

18.75 |

M20×1.5 |

22.5 |

17.50 |

4.75 |

M14×1.5 |

M20×1.5 |

20.0 |

18.75 |

M20×1.5 |

22.5 |

17.50 |

4.75 |

M16×2.0 |

M22×1.5 |

22.0 |

20.5 |

M22×1.5 |

24.5 |

17.75 |

6.35 |

M16×1.5 |

M22×1.5 |

22.0 |

20.5 |

M22×1.5 |

24.5 |

17.75 |

6.35 |

M18×1.5 |

M24×1.5 |

24.0 |

22.5 |

M24×1.5 |

26.5 |

19.75 |

6.35 |

M20×2.5 |

M30×2.0 |

30.0 |

28.0 |

M30×2.0 |

34.5 |

25.75 |

6.35 |

M20×1.5 |

M30×2.0 |

30.0 |

28.0 |

M30×2.0 |

34.5 |

25.75 |

6.35 |

M22×1.5 |

M32×2.0 |

32.0 |

30.0 |

M32×2.0 |

36.5 |

27.75 |

6.35 |

M24×3.0 |

M33×2.0 |

33.0 |

31.0 |

M33×2.0 |

37.5 |

28.75 |

6.35 |

M24×2.0 |

M33×2.0 |

33.0 |

31.0 |

M33×2.0 |

37.5 |

28.75 |

6.35 |

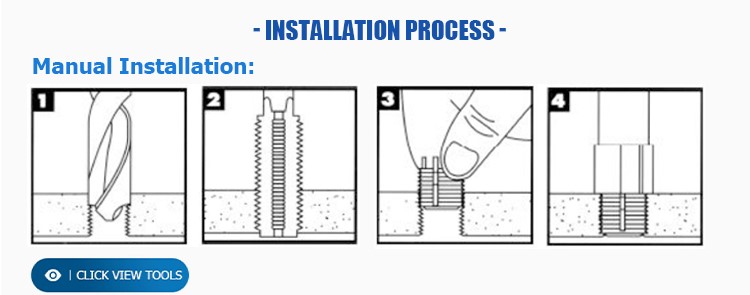

Product Installation Steps

1. Product Installation Steps

The tools and equipment required to install the key locking thread insert are: drill, tap, drilling plug, selection of the appropriate key locking thread insert, casing, and installation tools (usually a threaded cone and an adjustable handle).

2. Drill and tap

Use a suitable drill bit to drill the hole, or use a tap to clean the original threaded hole.

3. Install the key locking thread insert

Select the appropriate size of the key locking thread insert, insert it into the thread cone, and then insert it into the thread hole in the installation tool. Use a special installation tool to screw the key locking thread insert into the hole in the normal thread direction until the bottom of the key locking thread insert is flush with the thread hole.

4. Finish

Pull out the casing, and the latch sleeve is firmly installed in the original threaded hole along the threaded hole.

Matters needing attention

1. The dimensions between the key locking thread insert and the threaded hole must match.

2. Do not tighten the key locking thread insert too much, rotate it too much or install it in an inappropriate hole.

3. The depth of the key locking thread insert should be 1.5~2 times the depth of the thread hole.

4. If you feel difficult to install or have other problems during the installation process, stop the operation and seek professional help.