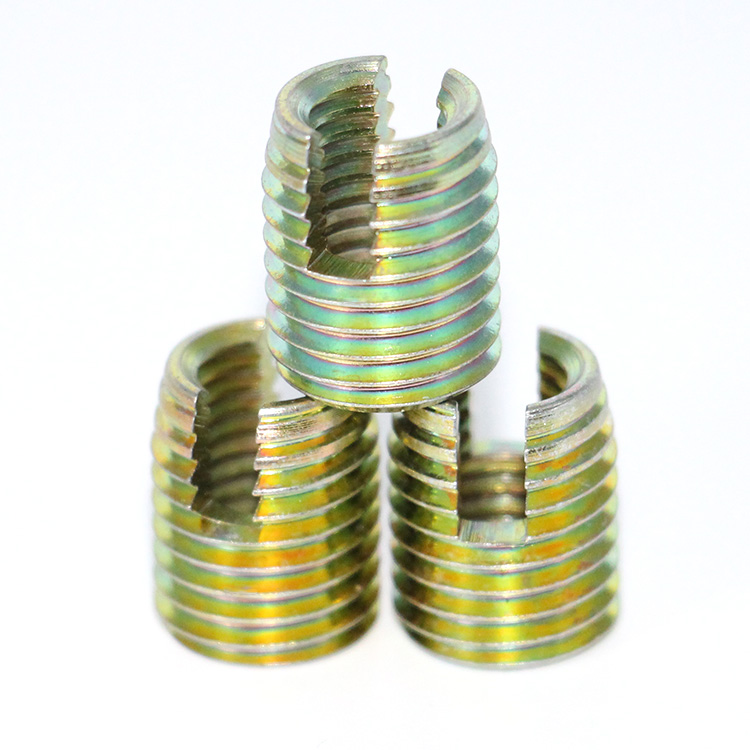

silvering plating wire screw threaded inserts

silvering plating wire screw threaded inserts

The wire thread insert is made of high-quality austenitic stainless steel material. It forms a reliable internal thread after installation and embedding. It can significantly improve the strength and safety of low-strength engineering materials such as aluminum, magnesium, copper alloy, plastic, plexiglass, and bakelite. Wear resistance; applied to steel parts, cast steel, and cast iron, it can improve the durability of screws, prevent screws from loosening and falling off, fatigue fracture due to various vibrations, and improve the fatigue resistance of screws during connection. The advantages of wire thread inserts are: high wear resistance and tensile strength, low thread friction, high surface quality, and excellent anti-corrosion and heat resistance.

The silver-plated steel wire screw sleeve is based on the ordinary type of steel wire screw sleeve, which can enhance the welding performance, corrosion resistance and thread connection performance of the steel wire screw sleeve.

The effect of stainless steel silver plating

The main functions of stainless steel silver plating include improving electrical conductivity, improving welding performance, enhancing corrosion resistance, and improving the performance of threaded connections.

Improve electrical conductivity and welding performance: stainless steel itself has poor electrical conductivity and solder performance, through silver plating treatment can significantly improve the electrical conductivity and solder performance of stainless steel, to meet the needs of electronic products for electrical conductivity and solder performance 1.

Enhanced corrosion resistance: silver plating layer has good corrosion resistance, can effectively protect the substrate from the erosion of environmental factors, extend the service life 2.

Improve thread connection performance: silver plating on the thread of the stainless steel sleeve joint nut, can form a good lubricating silver film, reduce friction between threads, prevent "biting" phenomenon, reduce the installation torque, easy to disassemble and install 3.

To sum up, silver plated stainless steel not only improves the physical properties of the material, such as electrical conductivity and weldability, also enhances the corrosion resistance of the material by forming a protective layer, at the same time improves the performance of threaded connection in specific applications, makes stainless steel widely used in more fields

The Advantages of Wire thread insert

Wear and Tear Stability

AVlC-Flight thread inserts are manufactured from austenitic chrome-nickel-steel (tensile strength of a minimum 1400 N/mm2).The formed thread provides a high surface quality. This guarantees a heavy-duty, wear and tear resistant thread with an extremely low constant thread friction force.This allows for a constant pre-stressing being achieved with the identical tightening torque upon repeated re-screwing. This leads simultaneously to a better utilisation of the yield point for high strength screws. The torsion stress is noticeably reduced hereby: In comparison with cut threads, the surface roughness depth is up to90% lower with AVlC-Flight thread inserts.

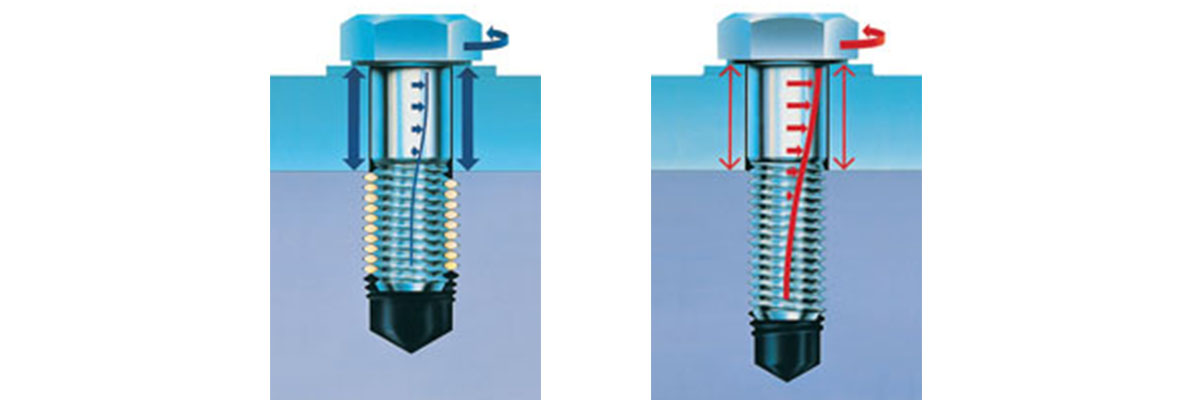

Stronger Assemblies

The flexible characteristics of the AVlC-Flight thread inserts provide an even loading and tension distribution and with that, a perfect thread pitch angle. Pitch and angle defects are balanced out over the entire length of the thread insert. Therefore an ideal force transfer is achieved between the bolt and the nut thread. The durability of the thread connection is significantly increased. This applies to both static and dynamic work loads.Use a shank removal tool to break off the tang of the installed wire threaded insert.

Corrosion Resistance, wide Temperature Range

The material properties of the Avic-Flight thread inserts ensure that locking and tight gripping of screw sunder normal environmental conditions does not occur. AVlC-Flight thread inserts made from nickel based materials (INCONEL and NIMONIC 90) are available for thermal high stressed thread connections,with or without any coating. Elasticity and springiness is preserved even under high temperatures.

AVlC-Flight thread inserts from high-strength hard coated aluminium has been specially developed for utilisation with materials liable to high corrosion such as magnesium. Contact corrosion is hereby ruled out.

Freedom of design

AVlC-Flight thread inserts allow a wide range for the designer in the choice of materials and material thickness. The actual trend towards light weight design (for example from magnesium) is fulfilled by AVlC-Flight thread inserts with highest loading capacity by means of thread reinforcement with its simultaneous low area requirement. Due to fewer connection points and a reduction in screw sizes,the saving of materials, size and weight with the same or higher requirements AVIC-Flight thread inserts leads to a substantial reduction in costs.

Fitting Stability

The outer diameter of the AVIC-Flight thread insert is larger than that of the tapped thread by a precisely calculated value in the non-fitted condition. This difference ensures, in addition to the inherent spring action of the AVIC-flight thread insert material radial expansion, a stable, play-free positioning in the nut thread.Additional fixing elements adhesives - such as required for fixed bushes-are no longer necessary.For utilisation of hammer driven screws please consult our technical consultant.