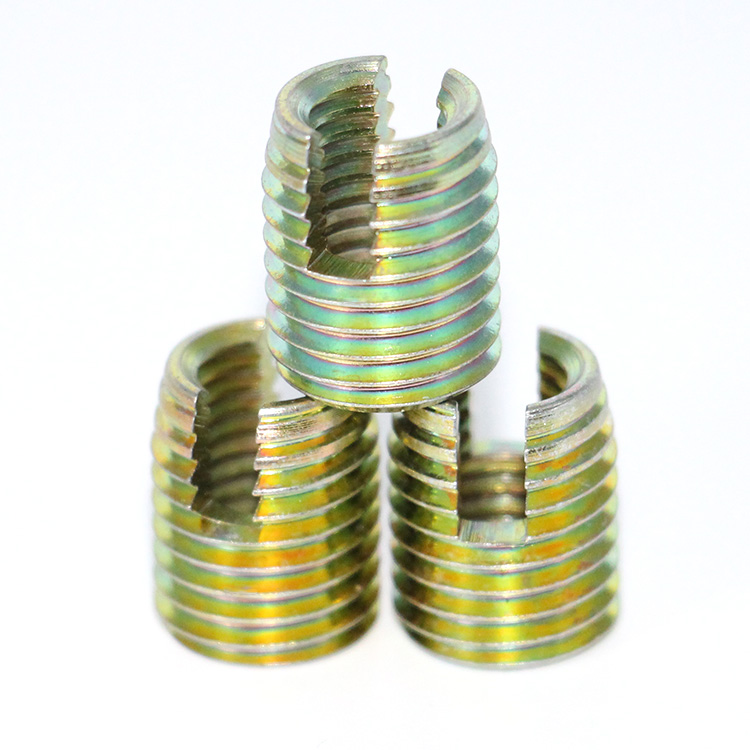

Slotted Self tapping thread insert for mental

3 hole Type Self tapping thread insert for mental

307/308 self-tapping thread insert are made of stainless steel and carbon steel two types, its basic application is very wide, mainly reflected in the thread protection, texture strong and texture repair and so on several aspects. 307/308 self-tapping thread insert are a kind of high-strength type of threaded fasteners, its inside and outside the screw threads, the three garden holes on it are used for tapping threads when installing, because 307/308 self-tapping thread insert are installed without the use of taps tapping threads, they themselves have the characteristics of self-tapping threads. Use a tap to tap threads, they themselves have the characteristics of self-tapping threads.

Self tapping thread insert parameter

Product name |

Self tapping thread insert |

Material |

Steel Zn/SUS303/Customized |

Surface color |

Galvanized/Natural color |

Galvanizing: yellow/blue/Colored | |

Thread type |

Metric,Inc UNC, UNF |

Model Number |

M2-M24/Customized |

Function |

Assembly, threaded connection/fastening/conversion |

Reliability test |

Mechanical dimentions, hardness test. salt spray endurance test |

Table of dimensions for self-tapping threaded inserts

Metric Size Type 307/308 self-tapping threaded inserts | |||||

|

Internal thread |

External thread |

Length |

Guideline values for receiving hole diameter |

Minimum borehole depth for blind holes |

|

A |

E |

P |

B |

L |

T |

M 3 |

5 |

0.5 |

4 |

4.7 to 4.8 |

6 |

M3 |

5 |

0.5 |

6 |

4.7 to 4.8 |

8 |

M3.5 |

6 |

0.5 |

5 |

5.6 to 5.7 |

7 |

M 3.5 |

6 |

0.75 |

8 |

5.6 to 5.7 |

10 |

M4 |

6.5 |

0.75 |

6 |

6.1 to 6.2 |

8 |

M 4 |

6.5 |

1 |

8 |

6.1 to 6.2 |

10 |

M5 |

8 |

0.6 |

7 |

7.6 to 7.7 |

9 |

M5 |

8 |

0.6 |

10 |

7.6 to 7.7 |

13 |

M6 |

10 |

0.8 |

8 |

9.5 to 9.6 |

10 |

M6 |

10 |

0.8 |

12 |

9.5 to 9.6 |

15 |

M8 |

12 |

0.8 |

9 |

11.3 to11.5 |

11 |

M8 |

12 |

0.8 |

14 |

11.3 to11.5 |

17 |

M10 |

14 |

1 |

10 |

13.3 to13.5 |

13 |

M10 |

14 |

1 |

18 |

13.3 to13.5 |

22 |

M12 |

16 |

1.25 |

12 |

15.2 to15.4 |

15 |

M12 |

16 |

1.25 |

22 |

15.2 to15.4 |

26 |

M14 |

18 |

1.5 |

14 |

17.2 to17.4 |

17 |

M14 |

18 |

1.5 |

24 |

17.2 to17.4 |

28 |

M16 |

20 |

1.5 |

14 |

19.2 to19.4 |

17 |

M16 |

20 |

1.5 |

24 |

19.2 to19.4 |

28 |

M18 |

22 |

1.75 |

18 |

21.2 to21.4 |

21 |

M18 |

22 |

1.75 |

24 |

21.2 to21.4 |

28 |

M20 |

26 |

2 |

27 |

25.2 to25.4 |

31 |

M22 |

26 |

2 |

30 |

25.2 to25.4 |

34 |

M24 |

30 |

2 |

30 |

29.2 to29.4 |

34 |

Inch Size Type 307/308 self-tapping threaded inserts | ||||

|

Internal thread |

External thread |

Length |

Minimum borehole depth |

|

A |

E |

P |

B |

T |

M3 |

5 |

0.6 |

4 |

6 |

M3.5 |

6 |

0.8 |

5 |

7 |

M4 |

6.5 |

0.8 |

6 |

8 |

M5 |

8 |

1 |

7 |

9 |

M6 |

10 |

1.25 |

8 |

10 |

M8 |

12 |

1.5 |

9 |

11 |

M10 |

14 |

1.5 |

10 |

13 |

M12 |

16 |

1.75 |

12 |

15 |

M14 |

18 |

2 |

14 |

17 |

M16 |

20 |

2 |

14 |

17 |

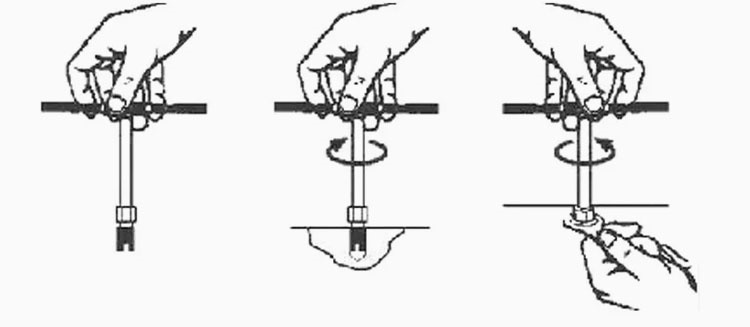

Product Installation Steps

Manual Installation:

Use the special thread insert installation tool. Refer to the figure below for the specific operation method. The end of the tool in the figure is a quadrangle head which can be connected with a manual tapping wrench.

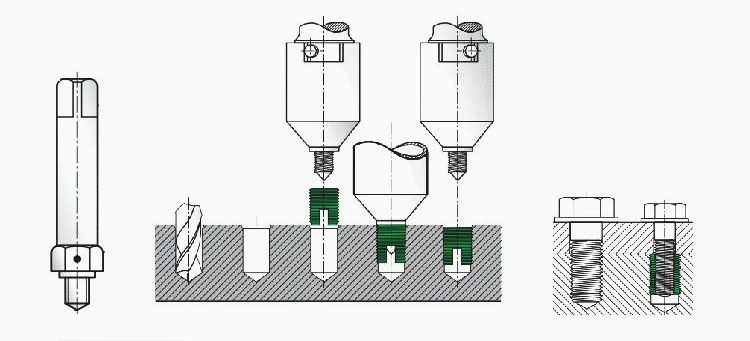

Electric Installation:

The Dill type of HRT numerical control suspension thread insert electric installation machine designed by AVIC can complete the installation of thread insert with high efficiency and high quality.

Attention during installation

1. For different processing materials, refer to the drilling size specification for pre-drilling processing. When the hardness of the corresponding material is high, please slightly increase the bottom hole within the drilling range.

2. With the slotted end of the socket down, install the self-tapping thread insert completely into the front of the tool, and it should be in vertical contact with the work piece. When installing (1 to 2 pitches), please make sure that the bottom hole is aligned and never tilt. If tilting is detected, do not reverse the tool and readjust before using. After 1/3 to 1/2 of the way in, do not start again. In addition, please do not reverse the rotation of the tool, otherwise it will cause product failure.

3. The self-tapping thread insert should be at least 1mm below the surface of the part after assembly.

Application of Self tapping threaded inserts

Self-tapping thread insert are thread inserts with slotted or open holes, with slotted thread insert being recommended for most applications. In some materials, this type of insert provides perfect specific thread locking. If this is not possible, the Type 307/308 is generally recommended and represents a major breakthrough in the area of difficult material cutting. With a very thick wall and three holes with cutting capacity dispersed in the wall, Type 307/308 is particularly suitable for use in materials with less generous thicknesses.

Generally there is no need to install the self-tapping thread insert for products that do not require it, but some important connection parts need to be installed due to high tension requirements or special design. Self-tapping screws are strictly according to the ISO/TS16949 quality system to produce and test products, self-tapping thread insert are used throughout almost the entire metal and plastics processing industry, the products have been used for a long time in the automotive industry, civil and commercial vehicle engines, transmissions, aerospace industry, railcar industry and so on, and its quality has never been questioned.

Part of the application industry display