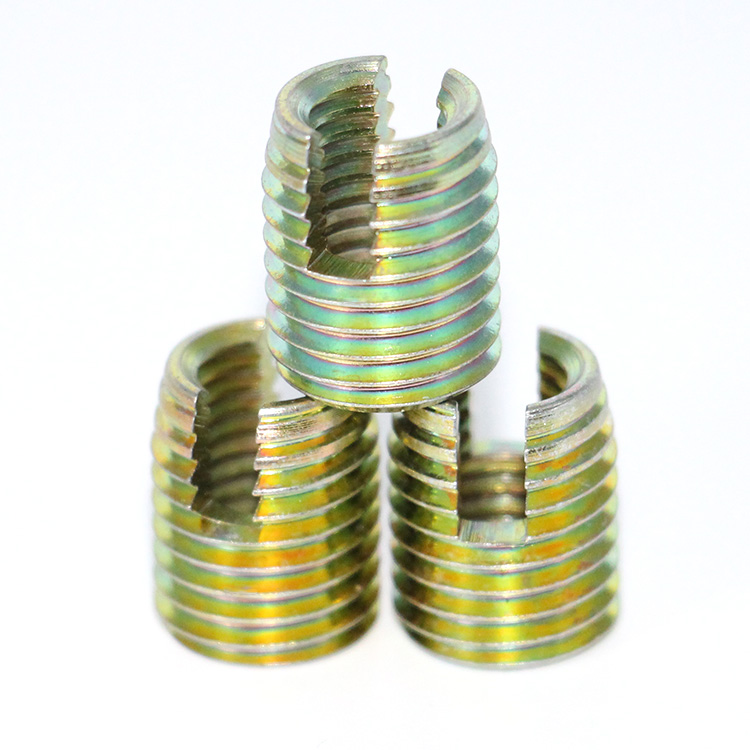

Stainless Steel Fastener Spring wire Threaded Inserts M6-M10

Stainless Steel Fastener Spring wire Threaded Inserts M6-M10

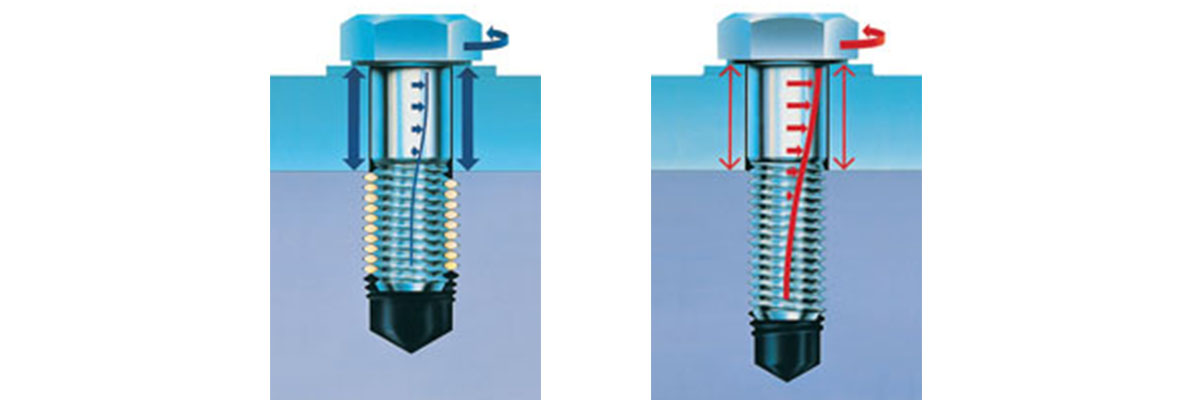

Wire thread insert is a new type of internal thread fastener, suitable for thread connection, screw and fastening in one of the threaded holes to be connected to form a standard internal thread, bolt (or screw) and then screwed into it, also known as thread sleeve, referred to as thread sleeve. It is a kind of spring like inner and outer thread concentric body made of cold rolled diamond stainless steel wire with high strength, high precision and smooth surface. It is mainly used to strengthen and protect the inner thread of low strength material. The principle is to form elastic connection between screw and matrix thread, eliminate thread manufacturing error and improve the connection strength. Wire embedding a screw aluminum, magnesium, iron, glass, plastic and other low strength of screw thread hole of engineering materials, can form in line with international standards of high-precision internal thread, has high bonding strength, the function of the earthquake, impact resistance and wear resistance, and can disperse stress to protect matrix thread, greatly extend the service life of the matrix, are widely used in electronic applications.

Wire Thread Insert Parameters

|

Product name |

Wire thread insert |

|

Material |

SUS304/SUS316/SUS321/InX750/Brass/Customized |

|

Surface color |

None / Eco-friendly plating |

|

Surface coating |

Silver/tin/cadmium/zinc/other |

|

Thread type |

Metric,Inc UNC, UNF |

|

Metric Size |

M1.4*0.3P~M85*6.0P |

|

Inch UNC Size |

1-64~11/2“-6 |

|

Inch UNF Size |

4-48~11/2“-12 |

|

Production standard |

MS21209/DIN8140/N926/ITN32760/MO-44421 |

Wire thread insert Common specifications parameter list

|

Diameter |

Pitch |

d |

(Dz) |

Bit diameter |

|

|

(d) |

(P) |

(do) |

|||

|

Metric |

|||||

|

M1.6 |

0.35 |

1d/1.5/2d/2.5d/3d |

2.08-2.18 |

1.7 |

|

|

M2 |

0.4 |

1d/1.5/2d/2.5d/3d |

2.60~2.80 |

2.1 |

|

|

M2.5 |

0.45 |

1d/1.5/2d/2.5d/3d |

3.30~3.50 |

2.6 |

|

|

M3 |

0.5 |

1d/1.5/2d/2.5d/3d |

3.80~4.00 |

3.2 |

|

|

M4 |

0.7 |

1d/1.5/2d/2.5d/3d |

5.05~5.25 |

4.2 |

|

|

M5 |

0.8 |

1d/1.5/2d/2.5d/3d |

6.35~6.60 |

5.2 |

|

|

M6 |

1 |

1d/1.5/2d/2.5d/3d |

7.60~7.85 |

6.3 |

|

|

M7 |

1 |

1d/1.5/2d/2.5d/3d |

8.65~8.90 |

7.3 |

|

|

M8 |

1.25 |

1d/1.5/2d/2.5d/3d |

9.85~10.10 |

8.4 |

|

|

M10 |

1.25 |

1d/1.5/2d/2.5d/3d |

12.10~12.50 |

10.4 |

|

|

M11 |

1.5 |

1d/1.5/2d/2.5d/3d |

13.10~13.50 |

11.5 |

|

|

M12 |

1.75 |

1d/1.5/2d/2.5d/3d |

14.40~14.80 |

12.5 |

|

|

Inch |

|||||

|

2-56 (0.086) |

0.435 |

1d/1.5d/2d/2.5d |

2.7~2.9 |

2.4 |

|

|

4-40 (0.112) |

0.635 |

1d/1.5d/2d/2.5d |

3.6~4.0 |

3.1 |

|

|

5-40 (0.125) |

0.635 |

1d/1.5d/2d/2.5d |

4.0~4.4 |

3.4 |

|

|

6-32 (0.138) |

0.794 |

1d/1.5d/2d/2.5d |

4.5~4.9 |

3.8 |

|

|

8-32 (0.164) |

0.794 |

1d/1.5d/2d/2.5d |

5.2~5.6 |

4.4 |

|

|

10-24 (0.190) |

1.058 |

1d/1.5d/2d/2.5d |

6.2~6.6 |

5.2 |

|

|

12-24 (0.216) |

1.058 |

1d/1.5d/2d/2.5d |

6.8~7.2 |

5.8 |

|

|

1/4"-20 |

1.27 |

1d/1.5d/2d/2.5d |

8.0~8.4 |

6.7 |

|

|

5/16"-18 |

1.411 |

1d/1.5d/2d/2.5d |

9.7~10.2 |

8.4 |

|

|

3/8"-16 |

1.588 |

1d/1.5d/2d/2.5d |

11.5~12.0 |

10 |

|

Action of wire threaded inserts

1. Enhance the connection strength and improve the connection conditions. Low strength materials such as aluminum and magnesium can avoid slipping and wrong teeth and obtain excellent connection performance.

2. Wear resistance. For frequently removed parts, can greatly increase the service life of thread.

3. Increase the force surface. It is used in places where strength connection is required and the diameter of thread hole cannot be increased.

3. Increase the force surface. It is used in places where strength connection is required and the diameter of thread hole cannot be increased.

5. Easy to maintain. The damaged thread hole into the wire thread insert, repair can continue to use, to avoid the possibility of loss of the work piece.

The Performance of Wire thread insert

Wire thread insert is a new fastening technology, which can effectively improve the connection conditions and greatly improve the reliability of screw connection. Its advantages are as follows:

1. Wire thread insert application in a variety of low strength materials, can largely improve the screw connection wear resistance, to avoid the damage of the connection thread.

2. Because the wire thread insert has a certain elasticity, can make the load distribution on the thread circle is more uniform, eliminate the screw pitch and tooth type deviation between the screw and thread hole, and can absorb vibration, so as to improve the connection strength and fatigue strength of the thread.