Stainless Steel Material Screw Fasteners Key - Locking Thread Insert

Stainless Steel Material Screw Fasteners Key - Locking Thread Insert

Key locking thread insert products are mainly used in military, aerospace, railway locomotives, vibration machinery and other products that require high thread strength.

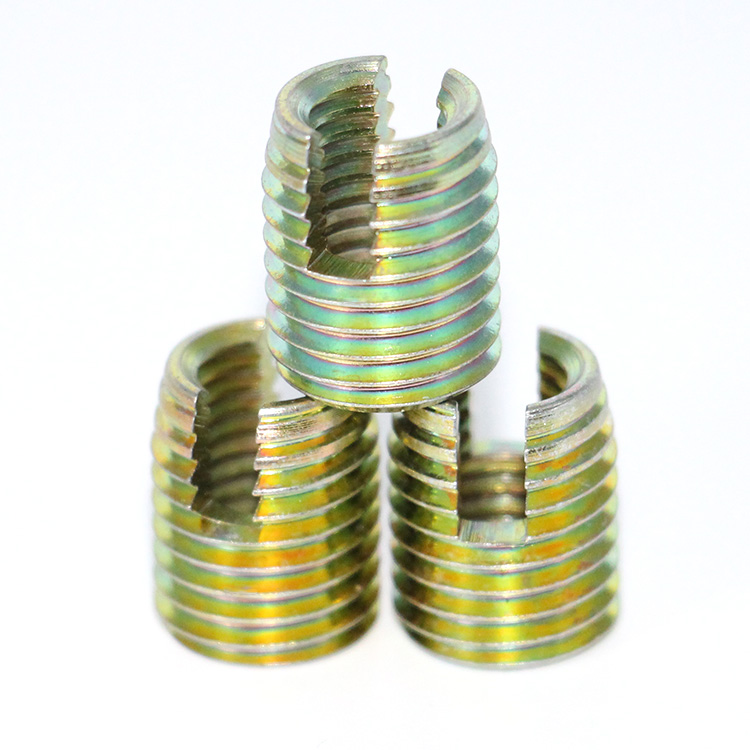

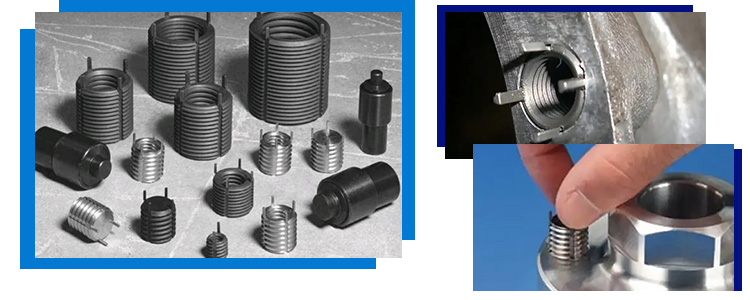

From the appearance of the product, the Key locking thread insert can be divided into thin-wall type and heavy-duty type. There are also reinforced and extra-heavy types.

The most basic function of the Key locking thread insert is to repair the internal thread and strengthen the external thread. As a thread repairing method, the Key locking thread insert can quickly and effectively repair damaged threads; it can be used on low-strength materials to greatly enhance the strength of the threaded hole.

Classification of Key locking threaded inserts

According to the shape and structure of the Key locking thread insert, the key locking thread insert be divided into two types: normal type and locking type.

The locking effect of the key lock thread insert is excellent and its key pin can fix it on the installed object. It is especially suitable for high-intensity vibration environment and can effectively resist earthquakes

On the basis of the none-locking type key locking insert, a locking slot is designed for the self-locking key locking insert, which makes its performance more superior.Self Locking type key locking insert, which has better shock resistance, more tight after installation

Key locking Thread Insert Parameters

Product name |

Key locking thread insert |

Finish |

Passivated |

Surface color |

None / Black anodised (carbon steel) |

Tolerances |

±.010 inch unless specified otherwise |

Internal Threads |

Per SAE AS8879 |

Dimensions |

All dimensions below are in inches |

Keys |

Inserts with an internal thread size of 5/16 and larger are furnished with 4 locking keys. Smaller sizes have 2 locking keys. |

Material Identification Mark |

None |

Lubrication |

Dry Film Lube on Self-locking Inserts only |

Performance |

MIL-I-45914A(MS51830&NAS1394) |

Metric size -Thin wall key locking thread insert | |||||||

|

Internal Thread

|

External Thread |

Length (mm) |

Tap Drill (mm) |

Thread Tap (mm) |

Tap Depth (mm) |

Removal Dril (mm) |

Removal Depth (mm) |

M5×0.8 |

M8×1.25 |

8.0 |

6.9 |

M8×1.25 |

9.5 |

5.50 |

4.00 |

M6×1.0 |

M10×1.25 |

10.0 |

8.8 |

M10×1.25 |

11.5 |

7.50 |

4.75 |

M8×1.25 |

M12×1.25 |

12.0 |

10.8 |

M12×1.25 |

13.5 |

9.50 |

4.75 |

M8×1.0 |

M12×1.25 |

12.0 |

10.8 |

M12×1.25 |

13.5 |

9.50 |

4.75 |

M10×1.5 |

M14×1.5 |

14.0 |

12.8 |

M14×1.5 |

15.5 |

11.50 |

4.75 |

M10×1.25 |

M14×1.5 |

14.0 |

12.8 |

M14×1.5 |

15.5 |

11.50 |

4.75 |

M12×1.75 |

M16×1.5 |

16.0 |

14.75 |

M16×1.5 |

17.5 |

13.50 |

4.75 |

M12×1.25 |

M16×1.5 |

16.0 |

14.75 |

M16×1.5 |

17.5 |

13.50 |

4.75 |

Metric size -Heavy duty key locking thread insert | |||||||

|

Internal Thread

|

External Thread |

Length (mm) |

Tap Drill (mm) |

Thread Tap (mm) |

Tap Depth (mm) |

Removal Dril (mm) |

Removal Depth (mm) |

M4×0.7 |

M8×1.25 |

8.0 |

6.9 |

M8×1.25 |

9.5 |

5.50 |

4.00 |

M5×0.8 |

M10×1.25 |

10.0 |

8.8 |

M10×1.25 |

12.5 |

7.50 |

4.75 |

M6×1.0 |

M12×1.25 |

12.0 |

10.8 |

M12×1.25 |

14.5 |

9.50 |

4.75 |

M8×1.25 |

M14×1.5 |

14.0 |

12.8 |

M14×1.5 |

16.5 |

11.50 |

4.75 |

M8×1.0 |

M14×1.5 |

14.0 |

12.8 |

M14×1.5 |

16.5 |

11.50 |

4.75 |

M10×1.5 |

M16×1.5 |

16.0 |

14.75 |

M16×1.5 |

18.5 |

13.50 |

4.75 |

M10×1.25 |

M16×1.5 |

16.0 |

14.75 |

M16×1.5 |

18.5 |

13.50 |

4.75 |

M12×1.75 |

M18×1.5 |

18.0 |

16.75 |

M18×1.5 |

20.5 |

15.50 |

4.75 |

M12×1.25 |

M18×1.5 |

18.0 |

16.75 |

M18×1.5 |

20.5 |

15.50 |

4.75 |

M14×2.0 |

M20×1.5 |

20.0 |

18.75 |

M20×1.5 |

22.5 |

17.50 |

4.75 |

M14×1.5 |

M20×1.5 |

20.0 |

18.75 |

M20×1.5 |

22.5 |

17.50 |

4.75 |

M16×2.0 |

M22×1.5 |

22.0 |

20.5 |

M22×1.5 |

24.5 |

17.75 |

6.35 |

M16×1.5 |

M22×1.5 |

22.0 |

20.5 |

M22×1.5 |

24.5 |

17.75 |

6.35 |

M18×1.5 |

M24×1.5 |

24.0 |

22.5 |

M24×1.5 |

26.5 |

19.75 |

6.35 |

M20×2.5 |

M30×2.0 |

30.0 |

28.0 |

M30×2.0 |

34.5 |

25.75 |

6.35 |

M20×1.5 |

M30×2.0 |

30.0 |

28.0 |

M30×2.0 |

34.5 |

25.75 |

6.35 |

M22×1.5 |

M32×2.0 |

32.0 |

30.0 |

M32×2.0 |

36.5 |

27.75 |

6.35 |

M24×3.0 |

M33×2.0 |

33.0 |

31.0 |

M33×2.0 |

37.5 |

28.75 |

6.35 |

M24×2.0 |

M33×2.0 |

33.0 |

31.0 |

M33×2.0 |

37.5 |

28.75 |

6.35 |

Advantage

1: threaded mounting pin sheath may effectively enhance the fastening strength and safety threaded hole, a threaded hole extended periods of time, improve product quality.

2: In some spark plugs, molds and other machinery and require frequent removal temperature of the thread holes on the corrosive bolt means threaded thread hole jacket may be enhanced wear resistant-corrosion resistant.

3: The Key locking thread insert has a repair function. When the screw thread of the machine's threaded hole slips due to various reasons, use the special tap of the bolt thread sheath for tapping, install the bolt thread sheath, and the threaded hole with the slippery thread can be quickly repaired.

4: The installation tools and installation methods of the Key locking thread insert are simple, and the installation is simple and can save time and improve work efficiency.

5: Key locking thread insert are installed on machinery molds, products that require very high threaded hole strength and fastening safety performance on products such as aerospace industry, products, automobile industry, and shipbuilding industry.